The Benefits of Using Plastic Custom Parts for Your Manufacturing Needs

When it comes to manufacturing custom parts, plastic is often the material of choice. This is because plastic custom parts offer a number of benefits that make them ideal for a variety of applications. Here are just a few of the advantages of using plastic custom parts for your manufacturing needs.

First, plastic custom parts are incredibly durable and long-lasting. Plastic is a strong and resilient material that can withstand a lot of wear and tear, making it ideal for parts that need to be used in a variety of environments. Additionally, plastic custom parts are resistant to corrosion, which makes them perfect for parts that will be exposed to moisture or other corrosive elements.

Second, plastic custom parts are also incredibly cost-effective. Plastic is a relatively inexpensive material, so you can get a lot of parts for a relatively low cost. This makes it ideal for companies that need to produce a large number of parts but don’t have a large budget.

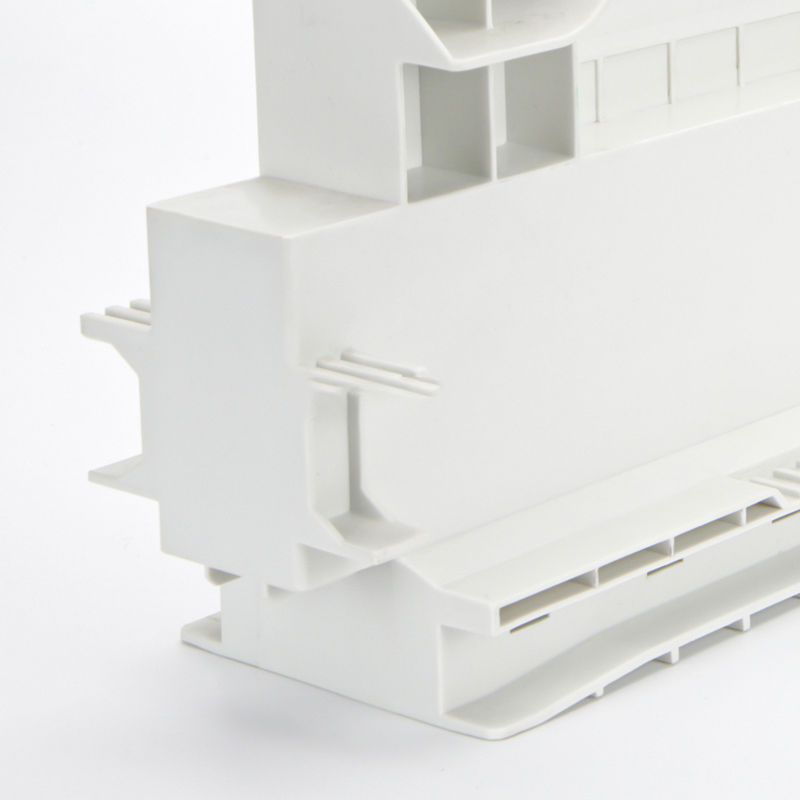

Third, plastic custom parts are also incredibly versatile. Plastic can be molded into almost any shape or size, making it perfect for parts that need to fit into tight spaces or have complex shapes. Additionally, plastic can be colored or textured to create a unique look for your parts.

Finally, plastic custom parts are also incredibly easy to work with. Plastic is a lightweight material that is easy to cut, shape, and form into the desired shape. This makes it ideal for parts that need to be quickly and easily assembled.

| Product Name | our services |

| Plastic injection molding parts | one-stop services |

Overall, plastic custom parts offer a number of advantages that make them ideal for a variety of manufacturing needs. From their durability and cost-effectiveness to their versatility and ease of use, plastic custom parts are an excellent choice for any manufacturing project.