The Advantages of 256 Poles Injection Molding Plastic Ferrite Magnet

The Advantages of 256 Poles Injection Molding Plastic Ferrite Magnet

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create a desired shape. One of the materials commonly used in injection molding is plastic ferrite, a type of magnet that is known for its excellent magnetic properties. In recent years, a new development in injection molding technology has emerged – the 256 poles injection molding plastic ferrite magnet. This article will explore the advantages of this innovative magnet and why it is gaining popularity in various industries.

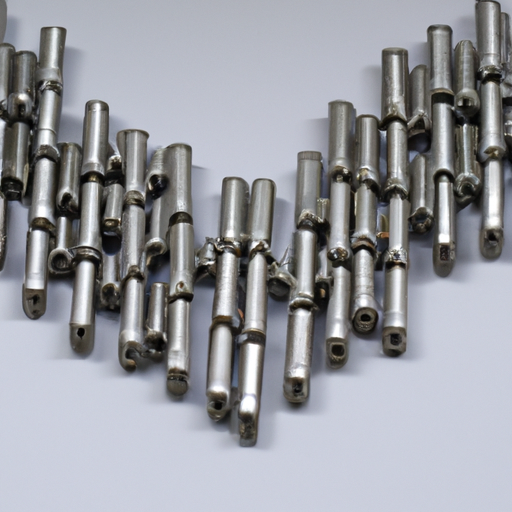

One of the key advantages of the 256 poles injection molding plastic ferrite magnet is its high magnetic strength. With 256 poles, this magnet is capable of generating a strong magnetic field, making it ideal for applications that require a powerful magnet. This increased magnetic strength allows for better performance in various devices and systems, such as motors, sensors, and magnetic separators.

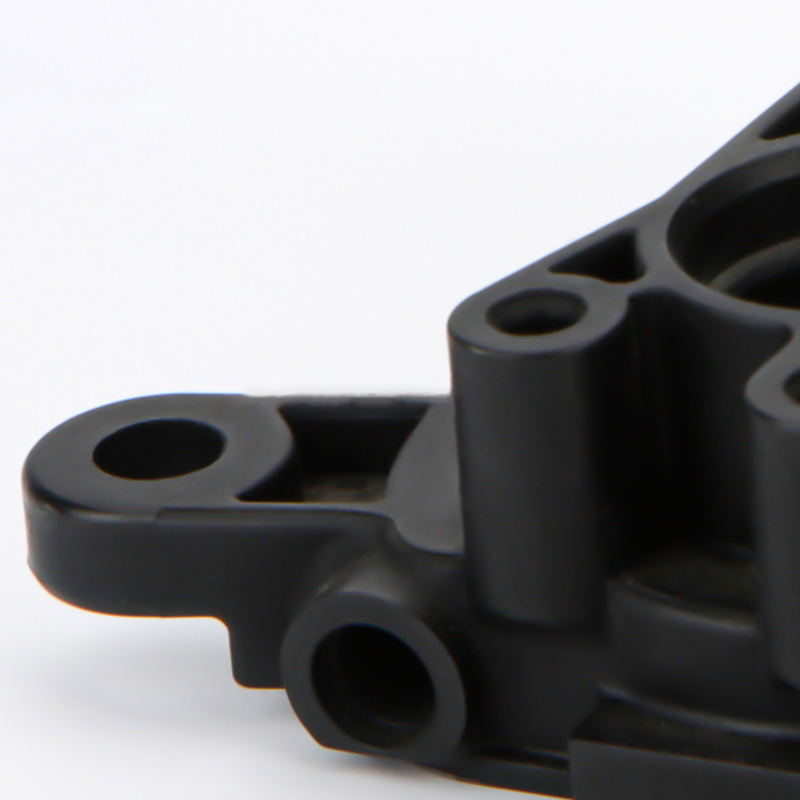

Another advantage of the 256 poles injection molding plastic ferrite magnet is its improved stability. The injection molding process ensures that the magnet is formed with a high level of precision, resulting in a magnet with consistent magnetic properties. This stability is crucial in applications where the magnet needs to maintain its magnetic strength over time, as any fluctuations could lead to a decrease in performance. With the 256 poles injection molding plastic ferrite magnet, manufacturers can have confidence in the magnet’s stability and reliability.

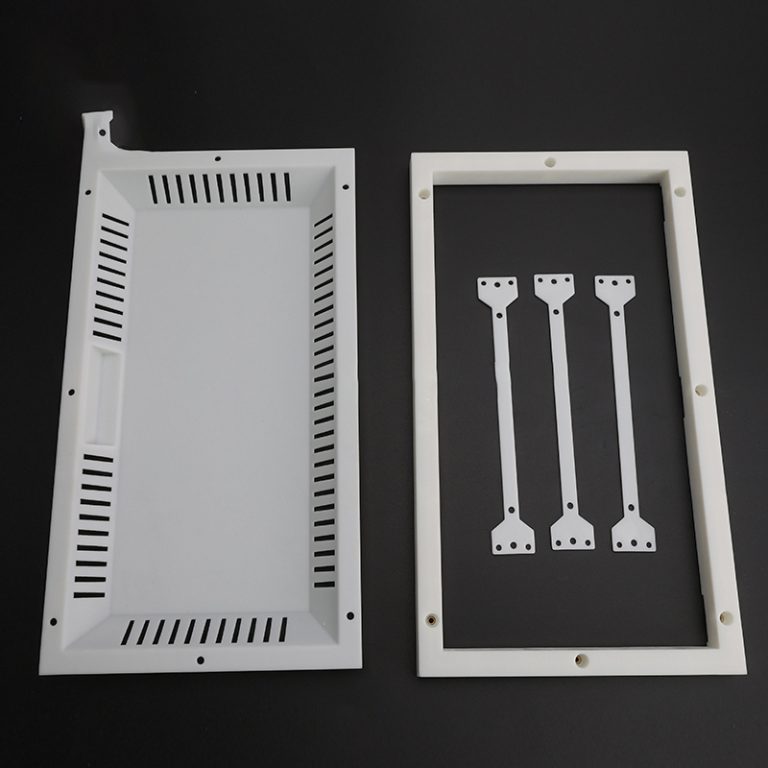

Furthermore, the 256 poles injection molding plastic ferrite magnet offers enhanced design flexibility. The injection molding process allows for complex shapes and intricate details to be achieved, giving designers more freedom in creating innovative magnet designs. This flexibility opens up new possibilities for magnet applications, as it enables the magnet to be tailored to specific requirements and fit into tight spaces. Whether it is a custom-shaped magnet for a medical device or a magnet with unique features for an automotive application, the 256 poles injection molding plastic ferrite magnet can meet the demands of various industries.

In addition to its magnetic properties and design flexibility, the 256 poles injection molding plastic ferrite magnet also offers cost advantages. The injection molding process is highly efficient and can produce magnets in large quantities at a relatively low cost. This makes the 256 poles injection molding plastic ferrite magnet a cost-effective solution for manufacturers who require magnets in high volumes. The ability to produce magnets at a lower cost without compromising on quality makes this magnet an attractive option for businesses looking to optimize their production processes.

| our services | size |

| one-stop services | customization |

In conclusion, the 256 poles injection molding plastic ferrite magnet offers several advantages that make it a preferred choice in various industries. Its high magnetic strength, improved stability, enhanced design flexibility, and cost advantages make it a versatile and reliable magnet for a wide range of applications. As injection molding technology continues to advance, we can expect further developments in magnet manufacturing, leading to even more efficient and powerful magnets in the future.