It seems like you’re interested in the use of structural foam in automotive applications, particularly regarding adhesives. Here’s some information on these topics:

1.Structural Foam in Automotive Applications:

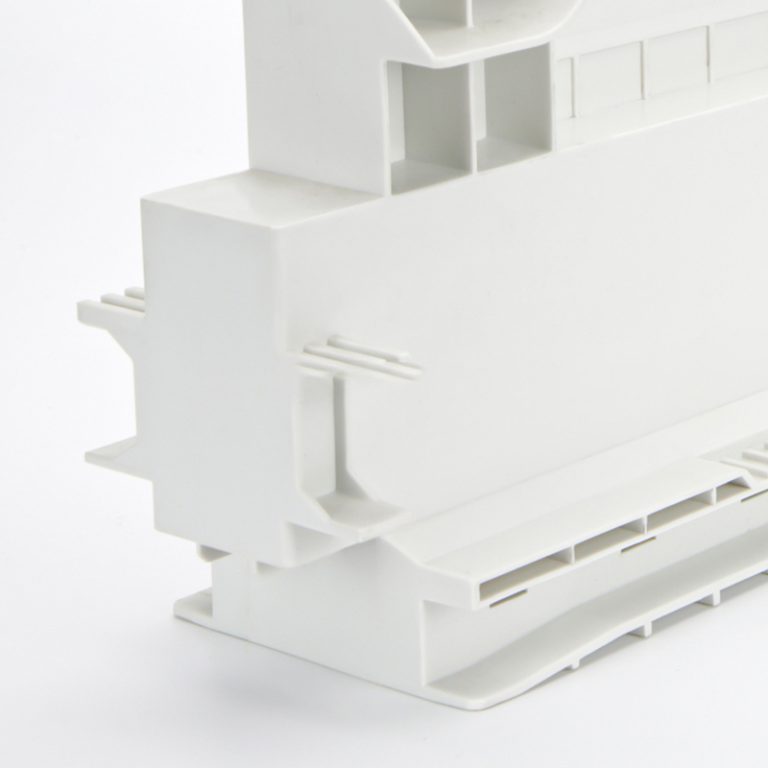

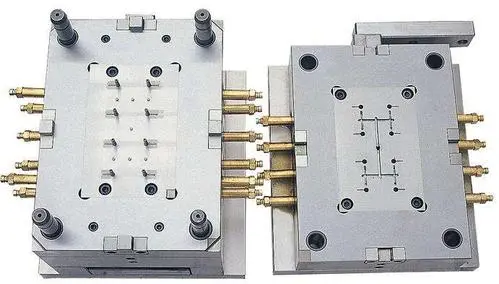

Structural foam is used in automotive manufacturing for various components due to its lightweight nature and strength. It can be utilized in parts such as bumpers, interior trim panels, underbody panels, and structural reinforcements. The foam structure helps reduce overall vehicle weight while maintaining structural integrity and impact resistance.

2.Structural Foam Adhesive:

Structural foam adhesive is specifically formulated to bond structural foam materials effectively. These adhesives are designed to provide high strength and durability, often used in automotive assembly to bond foam components securely without compromising performance. They can withstand the stresses and conditions typical in automotive environments, including temperature variations, vibrations, and exposure to fluids.

3.Benefits of Structural Foam in Automotive:

4.Weight Reduction: Helps achieve lightweighting goals, improving fuel efficiency and handling.

5.Strength and Rigidity: Provides structural integrity and stiffness to parts.

6.Impact Resistance: Offers good impact absorption properties, enhancing safety.

7.Design Flexibility: Allows for complex geometries and integrated features.

8.Noise and Vibration Dampening: Helps reduce noise and vibrations within the vehicle.

9.Applications:

| Automotive Industry |

| Furniture Manufacturing |

| Packaging Industry |

| Construction Sector |

| Electronics Industry |

| Sporting Goods |

| Marine Industry |

| Medical Equipment |

10.Bumpers: Structural foam can reinforce bumpers while absorbing impacts.

11.Interior Components: Used in panels, consoles, and trim for both aesthetic and functional purposes.

12.Underbody Panels: Enhances durability and protects critical components.

13.Structural Reinforcements: Provides strength in load-bearing parts of the vehicle.

In summary, structural foam plays a crucial role in modern automotive design and manufacturing, offering benefits such as weight reduction, enhanced strength, and design flexibility. Structural foam adhesives complement these properties by ensuring strong bonds between foam components, contributing to the overall performance and durability of automotive assemblies.