Benefits of Cheap Plastic Injection Molding for Small Businesses

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create various products. It is a cost-effective and efficient method, especially for small businesses looking to produce plastic parts or products in large quantities. In recent years, the availability of cheap plastic injection molding has made it even more accessible for small businesses, offering numerous benefits that can help them thrive in a competitive market.

One of the primary advantages of cheap plastic injection molding is its affordability. Traditional manufacturing methods, such as CNC machining or 3D printing, can be quite expensive, especially for small businesses with limited budgets. However, with cheap plastic injection molding, the initial setup costs are significantly lower. This means that small businesses can produce high-quality plastic parts or products at a fraction of the cost, allowing them to remain competitive and profitable.

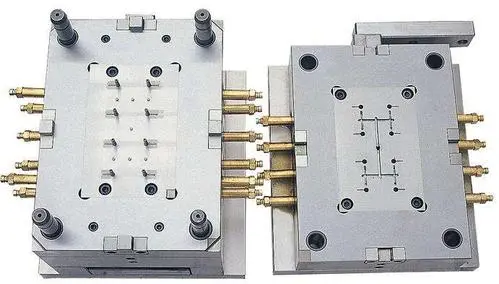

Moreover, cheap plastic injection molding offers a high level of precision and accuracy. The molds used in the process are designed with intricate details, ensuring that the final product is of superior quality. This is particularly important for small businesses that rely on the quality of their products to attract and retain customers. With cheap plastic injection molding, they can achieve the desired level of precision without compromising on the overall cost.

Another benefit of cheap plastic injection molding is its ability to produce complex shapes and designs. Unlike other manufacturing methods, such as CNC machining, which may have limitations when it comes to intricate designs, plastic injection molding can create products with intricate details and complex geometries. This opens up a world of possibilities for small businesses, allowing them to create unique and innovative products that stand out in the market.

Furthermore, cheap plastic injection molding offers a fast turnaround time. Once the mold is created and the production process is set up, the actual manufacturing process is relatively quick. This means that small businesses can produce large quantities of plastic parts or products in a short amount of time, meeting the demands of their customers and reducing lead times. This can be particularly advantageous for small businesses that operate in industries with high demand and fast-paced markets.

In addition to these benefits, cheap plastic injection molding also offers flexibility in terms of material selection. There is a wide range of plastic materials available for injection molding, each with its own unique properties and characteristics. Small businesses can choose the material that best suits their specific needs, whether it is for strength, flexibility, or heat resistance. This flexibility allows them to create products that meet the requirements of their target market, ensuring customer satisfaction and loyalty.

| Product Name | our services |

| Plastic injection molding parts | one-stop services |

In conclusion, cheap plastic injection molding offers numerous benefits for small businesses. Its affordability, precision, ability to produce complex shapes, fast turnaround time, and material flexibility make it an ideal manufacturing method for small businesses looking to produce plastic parts or products in large quantities. By taking advantage of cheap plastic injection molding, small businesses can remain competitive, produce high-quality products, and meet the demands of their customers, ultimately leading to their success and growth in the market.