Table of Contents

The Benefits of Clear Plastic Molding for Transparent Parts

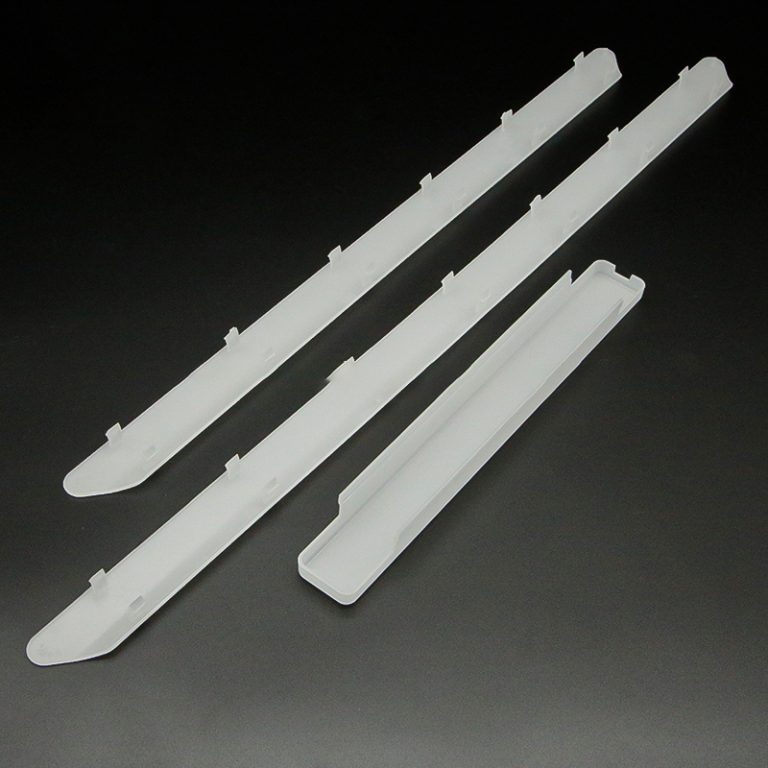

Clear plastic molding is a great way to create transparent parts for a variety of applications. This process involves injecting molten plastic into a mold to create a part with a desired shape and size. Clear plastic molding offers a number of benefits that make it an ideal choice for creating transparent parts.

First, clear plastic molding is cost-effective. The process is relatively simple and requires minimal setup, which helps to keep costs down. Additionally, the process is highly efficient, allowing for large volumes of parts to be produced quickly and easily. This makes it a great choice for applications that require a large number of parts in a short amount of time.

Second, clear plastic molding is highly customizable. The process allows for parts to be created in a variety of shapes and sizes, making it easy to create parts that meet specific requirements. Additionally, the process can be used to create parts with intricate details and complex shapes. This makes it a great choice for applications that require parts with unique designs.

Third, clear plastic molding is durable. The process creates parts that are strong and resistant to wear and tear. This makes them ideal for applications that require parts that can withstand harsh conditions. Additionally, the parts are resistant to corrosion and other environmental factors, making them a great choice for outdoor applications.

Finally, clear plastic molding is aesthetically pleasing. The process creates parts that are crystal clear, allowing for a high level of detail and clarity. This makes them ideal for applications that require parts that are visually appealing. Additionally, the parts can be colored or tinted to create a unique look.

Overall, clear plastic molding is a great choice for creating transparent parts. The process is cost-effective, highly customizable, durable, and aesthetically pleasing. This makes it an ideal choice for a variety of applications.

How to Choose the Right Clear Plastic Molding Process for Your Transparent Parts

When it comes to creating clear plastic parts, there are a variety of clear plastic molding processes to choose from. Each process has its own advantages and disadvantages, so it’s important to understand the differences between them in order to select the right one for your project.

The most common clear plastic molding processes are injection molding, blow molding, and thermoforming. Injection molding is the most popular process for creating clear plastic parts, as it is the most cost-effective and efficient way to produce large quantities of parts. Injection molding involves injecting molten plastic into a mold cavity, where it cools and hardens into the desired shape. This process is ideal for creating complex parts with tight tolerances.

| our services | size |

| one-stop services | customization |

Blow molding is another popular process for creating clear plastic parts. This process involves heating plastic pellets until they become molten, then forcing the molten plastic into a mold cavity using compressed air. This process is ideal for creating hollow parts with thin walls, such as bottles and containers.

Thermoforming is the process of heating a sheet of plastic until it becomes pliable, then forming it into the desired shape. This process is ideal for creating parts with complex shapes and intricate details.

When selecting the right clear plastic molding process for your project, it’s important to consider the size, complexity, and quantity of the parts you need to produce. Injection molding is the best choice for large quantities of parts with tight tolerances, while blow molding is ideal for hollow parts with thin walls. Thermoforming is best for parts with complex shapes and intricate details.

No matter which process you choose, it’s important to work with an experienced plastic molding company that has the expertise and resources to produce high-quality parts. With the right partner, you can be sure that your clear plastic parts will meet your exact specifications.