The Benefits of CNC Machined Plastic Parts for Your Manufacturing Process

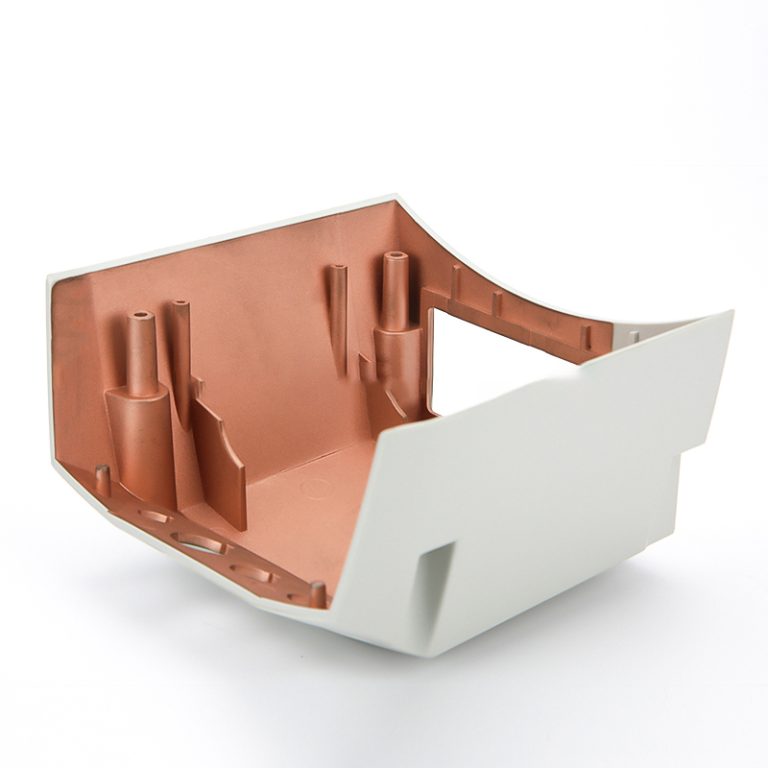

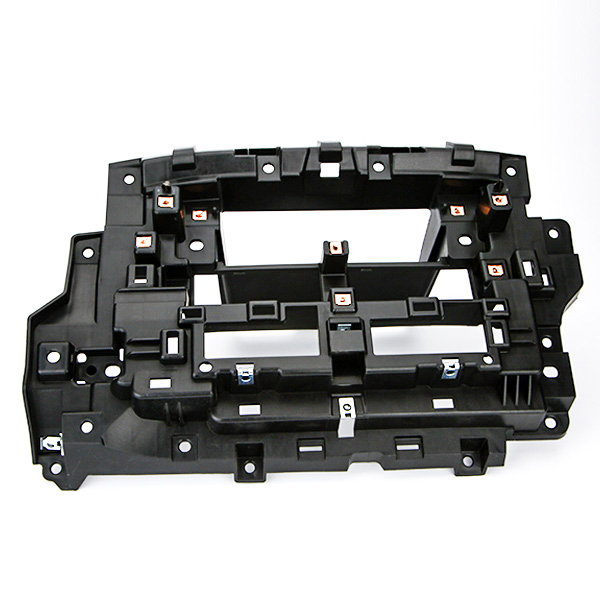

CNC machined plastic parts are becoming increasingly popular in the manufacturing industry due to their many benefits. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape plastic parts with precision and accuracy. This process is ideal for producing complex parts with tight tolerances and intricate details.

The first benefit of CNC machined plastic parts is that they are highly accurate. CNC machines are programmed to cut and shape the plastic parts with exact precision, ensuring that the parts are exactly as designed. This eliminates the need for manual labor and reduces the risk of human error. Additionally, CNC machining can produce parts with tight tolerances, which is essential for parts that need to fit together perfectly.

Another benefit of CNC machined plastic parts is that they are cost-effective. CNC machines are able to produce parts quickly and efficiently, which reduces the cost of production. Additionally, CNC machining eliminates the need for manual labor, which further reduces costs.

CNC machined plastic parts are also highly durable. The parts are cut and shaped with precision, which ensures that they are strong and long-lasting. This makes them ideal for use in a variety of applications, from automotive to medical.

Finally, CNC machined plastic parts are environmentally friendly. The process does not require the use of hazardous chemicals or materials, which reduces the environmental impact of the manufacturing process. Additionally, CNC machining produces less waste than traditional manufacturing processes, which further reduces its environmental impact.

| Material selection | colour |

| PP/PC/ABS/PET/PEEK/ETC. | OEM/ODM |

Overall, CNC machined plastic parts offer many benefits for the manufacturing process. They are highly accurate, cost-effective, durable, and environmentally friendly. As such, they are an ideal choice for any manufacturing process.