Benefits of Custom CNC Machining in Plastic Injection Molding

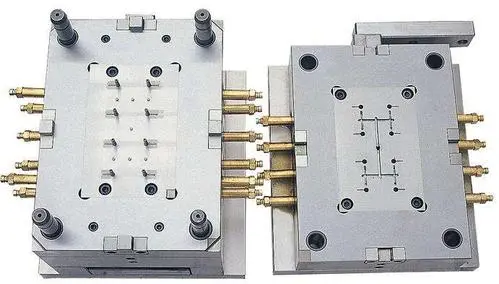

Custom CNC machining plays a crucial role in the plastic injection molding process, offering a wide range of benefits that can significantly improve the quality and efficiency of the final product. By utilizing advanced computer-controlled machinery, manufacturers can achieve precise and complex designs that would be difficult or impossible to achieve through traditional manufacturing methods.

One of the key advantages of custom CNC machining in plastic injection molding is the ability to create highly detailed and intricate parts with tight tolerances. CNC machines can produce parts with exceptional accuracy, ensuring that each component meets the exact specifications required for the final product. This level of precision is essential for industries such as aerospace, automotive, and medical, where even the smallest deviation can have serious consequences.

In addition to precision, custom CNC machining offers unparalleled versatility in terms of design flexibility. Manufacturers can easily modify and adjust the design of a part without the need for costly tooling changes, allowing for rapid prototyping and iteration. This flexibility is particularly valuable in industries where product development cycles are short and time-to-market is critical.

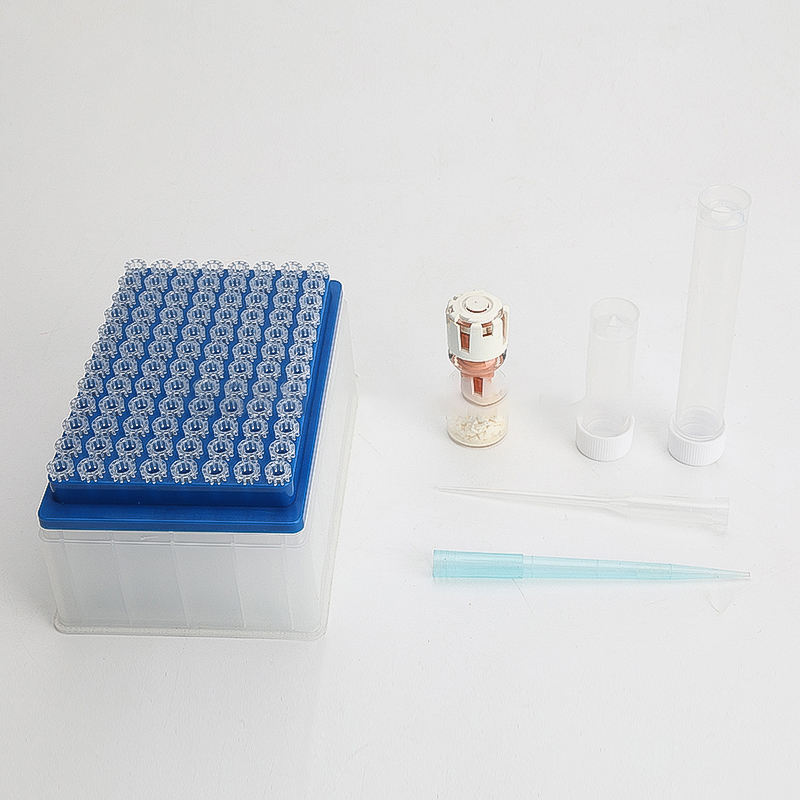

Furthermore, custom CNC machining enables manufacturers to work with a wide range of materials, including various types of plastics, metals, and composites. This versatility allows for greater design freedom and the ability to choose the most suitable material for each specific application. By selecting the right material, manufacturers can optimize the performance, durability, and cost-effectiveness of the final product.

Another significant benefit of custom CNC machining in plastic injection molding is the ability to produce high volumes of parts with consistent quality. CNC machines can operate continuously, 24/7, with minimal human intervention, ensuring consistent results and reducing the risk of errors or defects. This level of automation not only improves efficiency but also reduces production costs and lead times.

Moreover, custom CNC machining offers improved repeatability and scalability, making it ideal for mass production. Manufacturers can easily replicate the same design across multiple parts, ensuring uniformity and consistency throughout the production process. This scalability is essential for meeting the demands of large-scale manufacturing operations and maintaining high levels of quality control.

Additionally, custom CNC machining allows for the integration of advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These tools enable manufacturers to optimize the design and manufacturing process, identify potential issues early on, and make necessary adjustments to improve efficiency and quality. By leveraging these technologies, manufacturers can streamline production, reduce waste, and enhance overall productivity.

| Product Name | colour |

| Plastic injection molding parts | OEM/ODM |

In conclusion, custom CNC machining plays a vital role in plastic injection molding, offering a wide range of benefits that can significantly improve the quality, efficiency, and cost-effectiveness of the final product. By leveraging advanced technology, precision, versatility, and scalability, manufacturers can achieve superior results and stay competitive in today’s fast-paced market. Custom CNC machining is a valuable tool for any manufacturer looking to optimize their production process and deliver high-quality products to their customers.