Benefits of Using Custom Mold Plastic Injection Molding Service

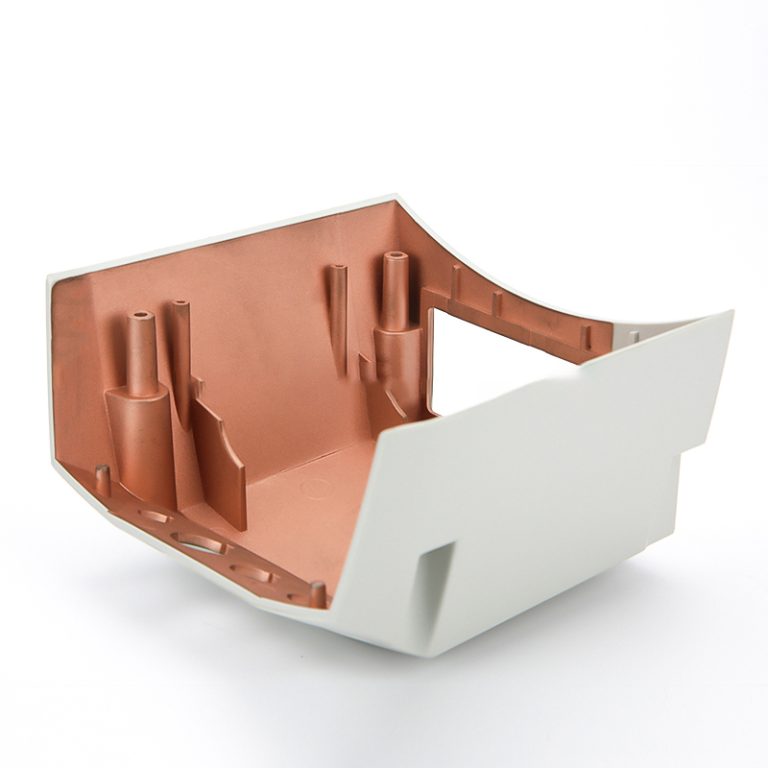

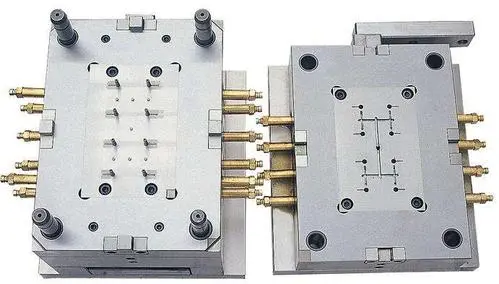

Custom mold plastic injection molding service offers a wide range of benefits for businesses looking to produce high-quality plastic parts efficiently and cost-effectively. This manufacturing process involves injecting molten plastic material into a custom-designed mold to create a specific shape or form. The use of custom molds allows for the production of complex and intricate parts with precision and consistency. In this article, we will explore the various advantages of using custom mold plastic injection molding service for your manufacturing needs.

| Material selection | colour |

| PP/PC/ABS/PET/PEEK/ETC. | OEM/ODM |

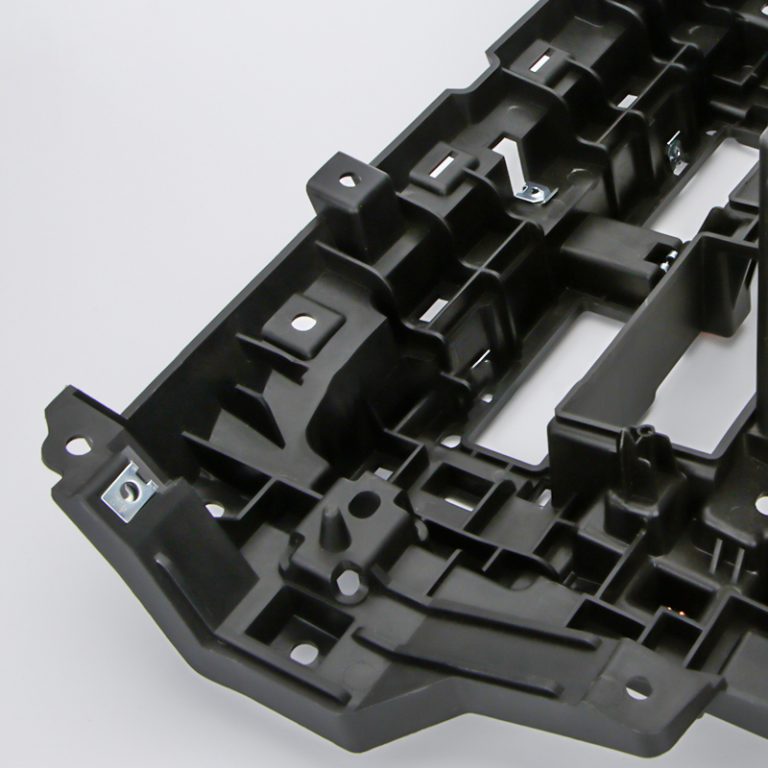

One of the key benefits of custom mold plastic injection molding service is the ability to produce parts with a high level of accuracy and detail. The custom-designed molds are created to exact specifications, ensuring that each part is produced with precision and consistency. This level of accuracy is essential for industries that require tight tolerances and intricate designs, such as the automotive, aerospace, and medical industries.

Another advantage of custom mold plastic injection molding service is the ability to produce parts in large quantities quickly and efficiently. The injection molding process is highly automated, allowing for fast production cycles and high output rates. This makes it an ideal manufacturing solution for businesses looking to scale up production and meet increasing demand for their products.

In addition to speed and efficiency, custom mold plastic injection molding service also offers cost savings for businesses. The use of custom molds reduces material waste and labor costs, as the molds can be reused multiple times for producing identical parts. This results in lower production costs per part, making injection molding a cost-effective manufacturing solution for businesses of all sizes.

Furthermore, custom mold plastic injection molding service allows for the production of parts with a wide range of materials, including thermoplastics, thermosets, and elastomers. This versatility in material selection makes injection molding suitable for a variety of applications across different industries. Whether you need parts that are rigid and durable or flexible and resilient, custom mold plastic injection molding service can meet your specific requirements.

Another benefit of using custom mold plastic injection molding service is the ability to incorporate design features and functionalities into the parts during the molding process. This includes adding inserts, overmolding, and multi-material molding to create parts with unique properties and characteristics. The flexibility of injection molding allows for the customization of parts to meet the specific needs and requirements of each project.

Moreover, custom mold plastic injection molding service offers a high level of repeatability and consistency in part production. The automated nature of the injection molding process ensures that each part is produced with the same level of quality and precision, regardless of the batch size. This consistency is crucial for maintaining product quality and meeting customer expectations.

In conclusion, custom mold plastic injection molding service provides numerous benefits for businesses looking to produce high-quality plastic parts efficiently and cost-effectively. From accuracy and speed to cost savings and material versatility, injection molding offers a comprehensive manufacturing solution for a wide range of industries. If you are looking to streamline your production process and improve the quality of your plastic parts, consider utilizing custom mold plastic injection molding service for your manufacturing needs.