Benefits of Using Custom Plastic Components in Manufacturing Operations

Custom plastic components play a crucial role in various manufacturing operations, offering a wide range of benefits that can enhance efficiency, productivity, and overall product quality. From automotive to electronics, custom plastic components are used in a multitude of industries to create products that meet specific requirements and standards. In this article, we will explore the advantages of using custom plastic components in manufacturing operations.

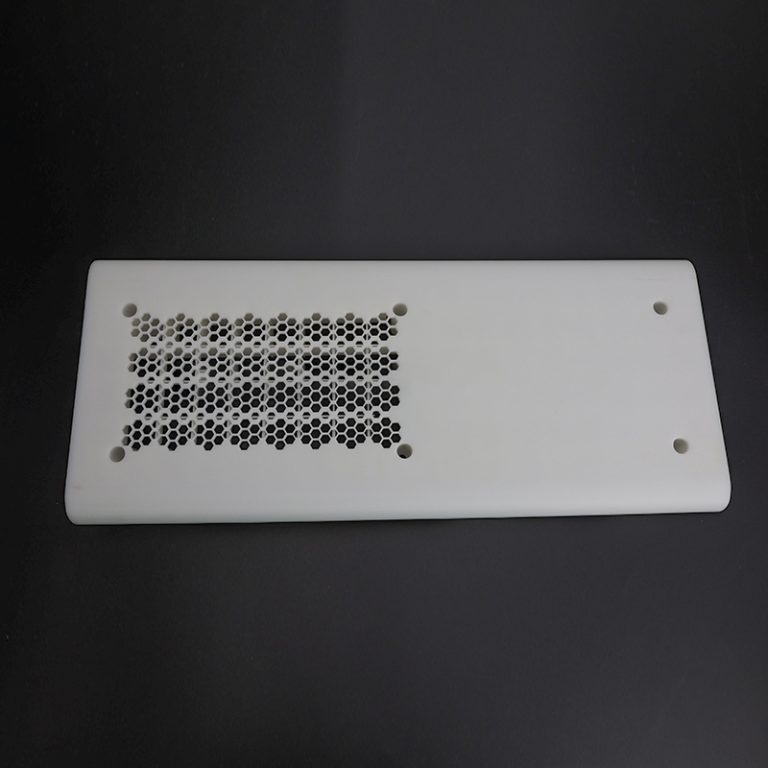

One of the key benefits of using custom plastic components is the ability to design and produce parts that are tailored to meet the exact specifications of a particular application. This level of customization allows manufacturers to create components that fit seamlessly into their products, resulting in improved performance and functionality. By working closely with a custom plastic component manufacturer, companies can ensure that their parts are designed to meet their unique requirements, whether it be size, shape, material, or color.

Another advantage of using custom plastic components is the flexibility they offer in terms of material selection. Custom plastic component manufacturers have access to a wide range of materials, each with its own unique properties and characteristics. This allows manufacturers to choose the material that best suits their specific needs, whether it be for strength, durability, flexibility, or resistance to chemicals and temperature extremes. By selecting the right material for their custom plastic components, manufacturers can ensure that their products perform optimally in their intended applications.

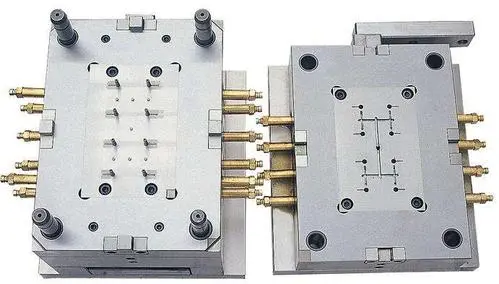

In addition to material selection, custom plastic components can also be manufactured using a variety of processes, such as injection molding, blow molding, and thermoforming. Each of these processes offers its own set of advantages, allowing manufacturers to choose the method that best suits their production requirements. For example, injection molding is ideal for producing high volumes of small to medium-sized parts with complex geometries, while blow molding is well-suited for creating hollow parts with uniform wall thickness. By leveraging the capabilities of different manufacturing processes, manufacturers can achieve cost-effective production of custom plastic components without compromising on quality.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

Furthermore, custom plastic components are lightweight and corrosion-resistant, making them ideal for a wide range of applications. Their lightweight nature reduces overall product weight, which can lead to cost savings in shipping and handling. Additionally, their corrosion resistance ensures that they can withstand harsh environmental conditions without deteriorating or degrading over time. This makes custom plastic components a durable and long-lasting solution for manufacturers looking to create products that can withstand the rigors of everyday use.

Overall, the benefits of using custom plastic components in manufacturing operations are numerous. From customization and material selection to manufacturing processes and performance characteristics, custom plastic components offer a versatile and cost-effective solution for creating high-quality products. By leveraging the expertise of custom plastic component manufacturers, companies can design and produce parts that meet their specific requirements and exceed their customers’ expectations. Whether it be for automotive, electronics, consumer goods, or industrial applications, custom plastic components play a vital role in driving innovation and success in the manufacturing industry.