Avantages du moulage par injection personnalisé pour les produits en plastique

Sélection du matériau

| taille | ABS/PET/PEEK/ETC. |

| personnalisation | En conclusion, le moulage par injection personnalisé offre de nombreux avantages aux fabricants cherchant à produire des produits en plastique de haute qualité avec précision, efficacité et rentabilité. Le processus permet la création de conceptions complexes, une qualité de produit constante et une production rentable, ce qui en fait une solution de fabrication polyvalente et fiable pour un large éventail d’industries. En tirant parti des avantages du moulage par injection personnalisé, les fabricants peuvent obtenir une plus grande flexibilité de conception, une plus grande cohérence des produits et des économies de coûts, améliorant ainsi leur compétitivité sur le marché. |

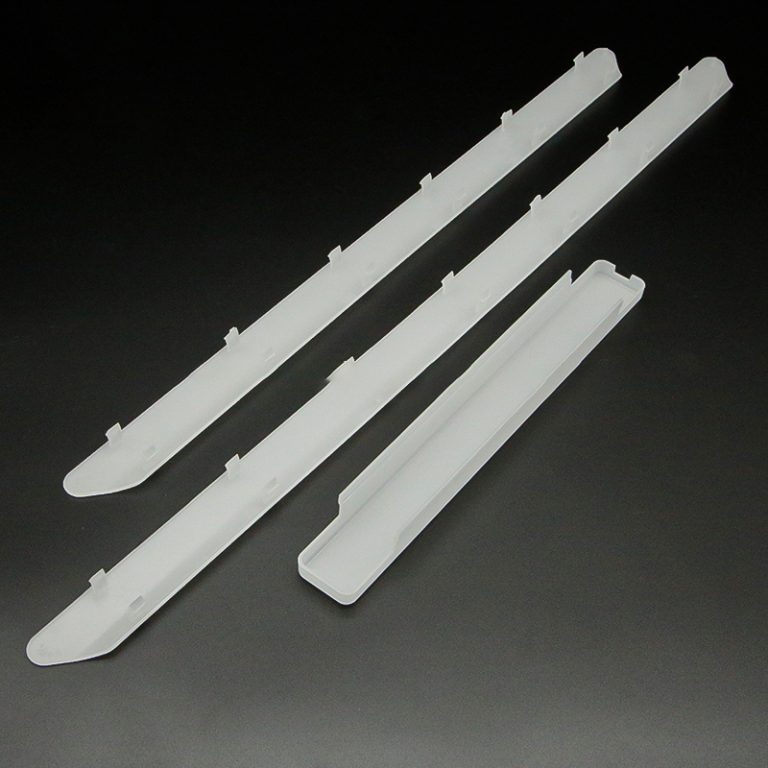

Custom injection molding is also a cost-effective manufacturing solution for plastic products. The high production efficiency of the process allows for large volumes of products to be manufactured quickly and efficiently, reducing labor costs and overall production time. Additionally, the use of thermoplastics in injection molding results in minimal material waste, further lowering production costs and making it an environmentally friendly option for manufacturers.

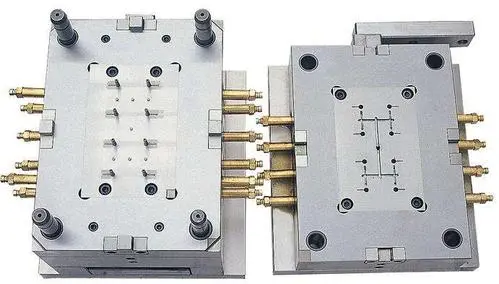

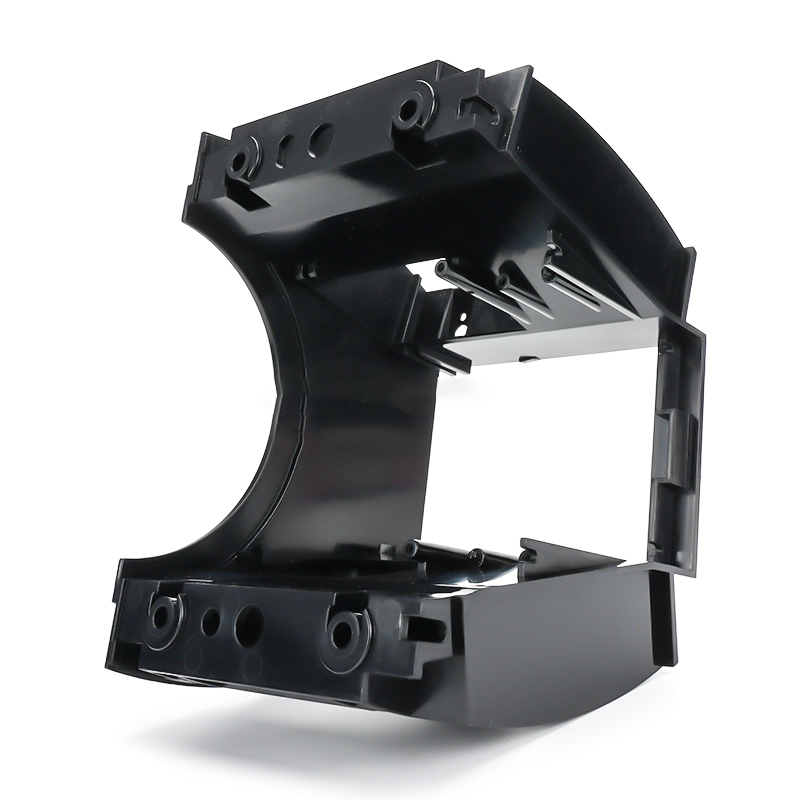

Another benefit of custom injection molding is the ability to incorporate various features and functionalities into a single product. By using multi-cavity molds and advanced tooling techniques, manufacturers can produce complex parts with multiple components in a single operation, reducing assembly time and costs. This capability is particularly advantageous for industries that require intricate and integrated product designs, such as consumer electronics and medical devices.

Furthermore, custom injection molding allows for the production of high-quality and durable plastic products that are resistant to wear, corrosion, and impact. The use of advanced materials and additives in the molding process can enhance the strength, flexibility, and longevity of plastic products, making them suitable for a wide range of applications and environments. This durability is especially important for industries that require products to withstand harsh conditions, such as automotive, industrial, and outdoor equipment.

In conclusion, custom injection molding offers numerous benefits for manufacturers seeking to produce high-quality plastic products with precision, efficiency, and cost-effectiveness. The process allows for the creation of complex designs, consistent product quality, and cost-effective production, making it a versatile and reliable manufacturing solution for a wide range of industries. By leveraging the advantages of custom injection molding, manufacturers can achieve greater design flexibility, product consistency, and cost savings, ultimately enhancing their competitiveness in the market.