Table of Contents

Benefits of Using High Quality Plastic Crates in Injection Molding Processes

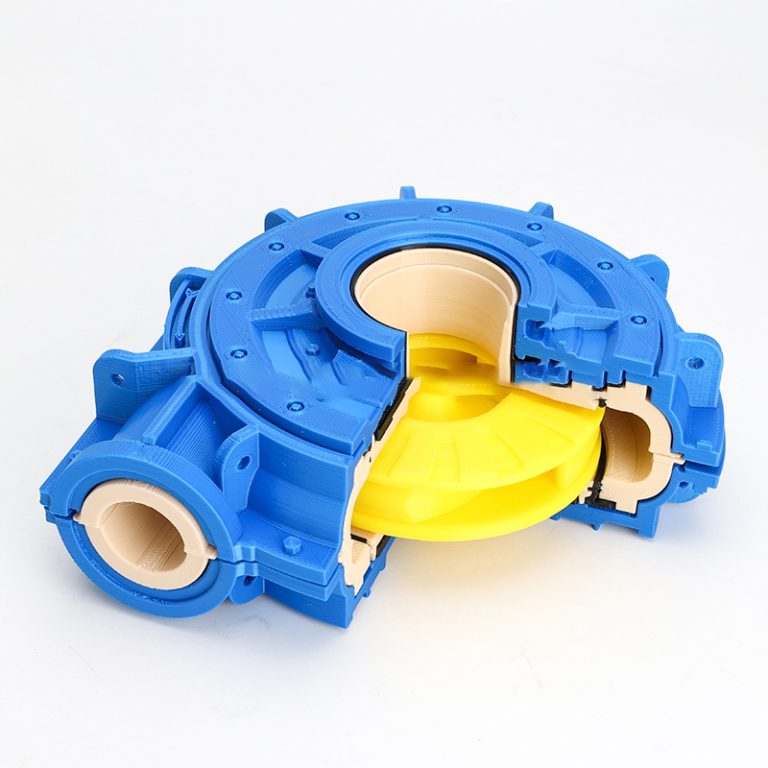

Plastic crate injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity to create a specific shape. This process is commonly used in the production of plastic crates, which are essential for storing and transporting goods in various industries. When it comes to plastic crate injection molding, the quality of the plastic crates produced plays a crucial role in determining the overall efficiency and effectiveness of the manufacturing process.

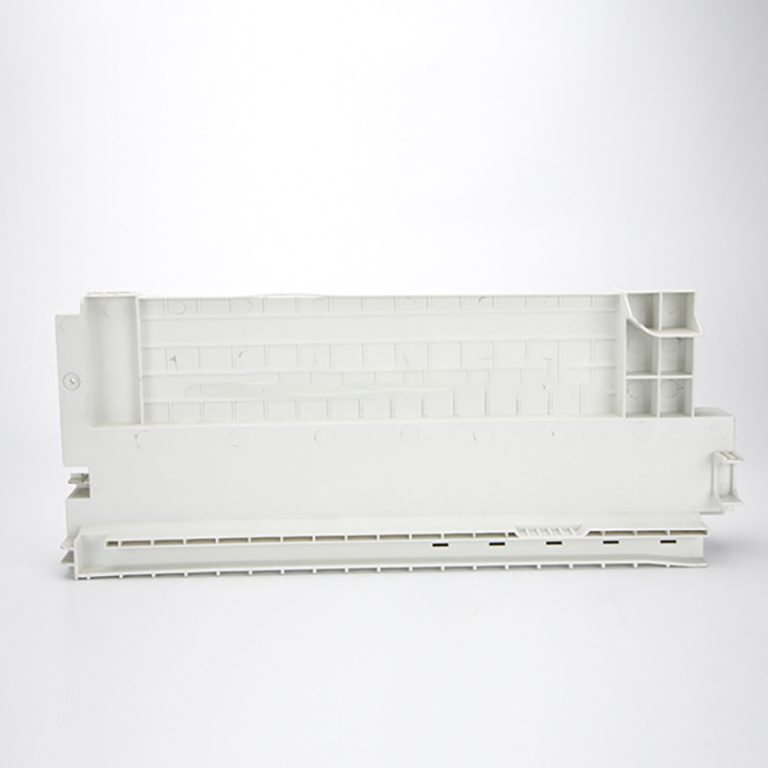

One of the key benefits of using high-quality plastic crates in injection molding processes is the durability and strength they offer. High-quality plastic crates are made from premium materials that are designed to withstand heavy loads and rough handling. This means that they are less likely to break or deform during use, ensuring that the goods stored inside remain safe and secure. In addition, high-quality plastic crates are also resistant to chemicals, moisture, and extreme temperatures, making them suitable for a wide range of applications.

Another advantage of using high-quality plastic crates in injection molding processes is the consistency and precision they provide. High-quality plastic crates are manufactured using advanced injection molding techniques that ensure uniformity in shape, size, and thickness. This level of consistency is essential for ensuring that the plastic crates fit together seamlessly and stack neatly, maximizing storage space and efficiency. Additionally, high-quality plastic crates are less likely to have defects or imperfections, reducing the need for rework and ensuring a higher level of product quality.

Furthermore, high-quality plastic crates offer enhanced customization options, allowing manufacturers to create crates that meet their specific requirements. High-quality plastic crates can be easily customized in terms of color, size, shape, and design, making them suitable for a wide range of applications. Whether you need plastic crates for storing food products, automotive parts, or electronic components, high-quality plastic crates can be tailored to meet your exact needs. This level of customization not only enhances the functionality of the plastic crates but also helps to strengthen your brand identity and differentiate your products from competitors.

In addition to durability, consistency, and customization, high-quality plastic crates also offer cost savings in the long run. While high-quality plastic crates may have a higher upfront cost compared to lower-quality alternatives, they are more durable and long-lasting, reducing the need for frequent replacements. This can result in significant cost savings over time, as you won’t have to constantly invest in new plastic crates. Furthermore, high-quality plastic crates are more efficient in terms of storage and transportation, allowing you to maximize space and reduce shipping costs.

Overall, the benefits of using high-quality plastic crates in injection molding processes are clear. From durability and consistency to customization and cost savings, high-quality plastic crates offer a range of advantages that can help improve the efficiency and effectiveness of your manufacturing operations. By investing in high-quality plastic crates, you can ensure that your products are stored and transported safely and securely, while also enhancing your brand image and reducing long-term costs.

How to Choose the Right Manufacturer for High Quality Plastic Crate Injection Molding Services

Plastic crate injection molding is a popular manufacturing process used to produce high-quality plastic crates for various industries. These crates are essential for transporting and storing goods, making them a crucial component of many businesses’ operations. When it comes to choosing a manufacturer for plastic crate injection molding services, it is important to select a company that can deliver high-quality products that meet your specific requirements.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

One of the key factors to consider when choosing a manufacturer for plastic crate injection molding services is the quality of their products. High-quality plastic crates are durable, strong, and able to withstand the rigors of transportation and storage. A reputable manufacturer will use top-of-the-line materials and state-of-the-art equipment to ensure that their products meet the highest standards of quality.

In addition to quality, it is also important to consider the manufacturer’s experience and expertise in plastic crate injection molding. An experienced manufacturer will have a deep understanding of the injection molding process and will be able to produce crates that meet your exact specifications. They will also be able to offer valuable insights and recommendations to help you optimize your crate design and production process.

Another important factor to consider when choosing a manufacturer for plastic crate injection molding services is their production capacity. It is essential to select a manufacturer that can meet your production needs and deliver your crates in a timely manner. A manufacturer with a large production capacity will be able to handle high-volume orders and ensure that you receive your crates when you need them.

When evaluating potential manufacturers, it is also important to consider their reputation in the industry. A reputable manufacturer will have a track record of delivering high-quality products and excellent customer service. You can research online reviews and testimonials to get a sense of the manufacturer’s reputation and reliability.

Cost is another important consideration when choosing a manufacturer for plastic crate injection molding services. While it is important to find a manufacturer that offers competitive pricing, it is also crucial to consider the overall value that they provide. A manufacturer that offers high-quality products, excellent customer service, and timely delivery may be worth paying a slightly higher price for.

Communication is key when working with a manufacturer for plastic crate injection molding services. It is important to choose a manufacturer that is responsive, transparent, and easy to communicate with. Clear and open communication will help ensure that your project runs smoothly and that any issues or concerns are addressed promptly.

In conclusion, choosing the right manufacturer for high-quality plastic crate injection molding services is essential for businesses that rely on plastic crates for their operations. By considering factors such as quality, experience, production capacity, reputation, cost, and communication, you can select a manufacturer that meets your specific requirements and delivers top-notch products. Investing time and effort into finding the right manufacturer will pay off in the long run with high-quality plastic crates that meet your needs and exceed your expectations.