Table of Contents

Step-by-Step Guide to Making a Mold for Plastic Parts: What You Need to Know

A: Alright, let’s get started on making a mold for plastic parts. What do we need to know?

B: Well, the first step is to decide what type of plastic part you want to make. Different plastics require different molds.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

A: Got it. What else?

B: Next, you’ll need to create a prototype of the part you want to make. This will be used to create the mold.

A: How do I do that?

B: You can use a 3D printer or a CNC machine to create a prototype. Once you have the prototype, you can use it to create a mold.

A: What kind of mold do I need?

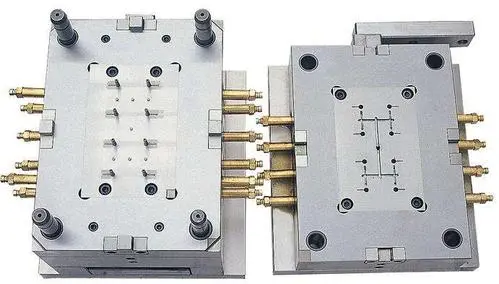

B: Depending on the type of plastic part you’re making, you’ll need either an injection mold or a compression mold. Injection molds are used for thermoplastics, while compression molds are used for thermosets.

A: Okay, so I have the prototype and the type of mold I need. What’s next?

B: Now you’ll need to create the mold itself. This involves machining the mold out of metal or plastic. You’ll also need to create the mold cavity, which is the space where the plastic will be injected or compressed.

A: Got it. Anything else?

B: Once the mold is complete, you’ll need to test it to make sure it works properly. This involves running a few test runs with the plastic material you’re using. Once you’re satisfied with the results, you can start producing your plastic parts.

The Benefits of Using a Mold for Plastic Parts: Why It’s Worth the Investment

“So, why should I invest in a mold for plastic parts?”

“Well, there are several benefits to using a mold for plastic parts. First, it allows you to produce parts with a high degree of accuracy and repeatability. This means that you can produce parts that are consistent in size, shape, and quality.

Second, it allows you to produce parts quickly and efficiently. With a mold, you can produce multiple parts in a single cycle, which can save you time and money.

Third, it allows you to produce parts with complex shapes and features. This means that you can create parts with intricate details that would be difficult to produce with other methods.

Finally, it allows you to produce parts with a high degree of durability. The parts produced with a mold are more resistant to wear and tear, which can help extend the life of the part.

Overall, investing in a mold for plastic parts is a worthwhile investment. It can help you produce parts with greater accuracy, efficiency, and durability, which can save you time and money in the long run.”