The Importance of Mold Maker in Plastic Injection Molding Processes

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create various products. This process is highly efficient and cost-effective, making it a popular choice for producing large quantities of plastic parts. However, the success of plastic injection molding heavily relies on the expertise of mold makers.

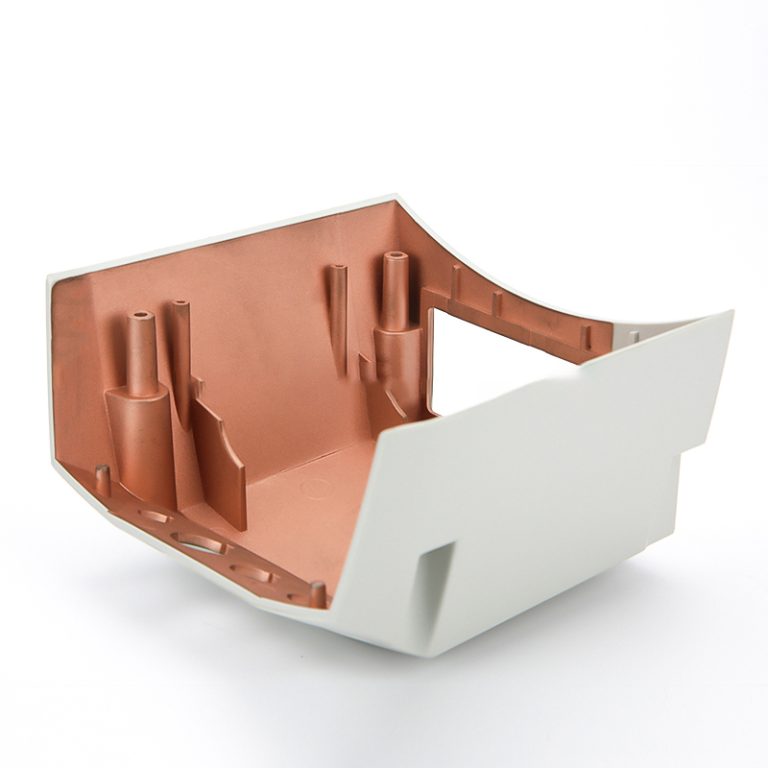

Mold makers play a crucial role in the plastic injection molding process. They are responsible for designing and creating the molds that will be used to shape the plastic material. These molds need to be precise and durable to ensure the production of high-quality plastic parts. Mold makers use advanced computer-aided design (CAD) software to create detailed 3D models of the molds, taking into account factors such as material flow, cooling, and ejection.

The importance of mold makers in plastic injection molding cannot be overstated. Their expertise and attention to detail are essential in ensuring that the molds are designed correctly. A poorly designed mold can lead to defects in the final product, such as warping, sink marks, or flash. These defects not only affect the appearance of the product but also its functionality and durability. Mold makers must consider various factors, such as the type of plastic material, the desired shape and size of the product, and the production volume, to create molds that meet the specific requirements of each project.

| our services | size |

| one-stop services | customization |

Furthermore, mold makers must also consider the cost and time constraints of the project. They need to find a balance between creating molds that are cost-effective and efficient while still producing high-quality parts. This requires a deep understanding of the plastic injection molding process and the ability to optimize the design of the molds. Mold makers often collaborate closely with engineers and designers to ensure that the molds meet the desired specifications while also being practical and feasible for production.

In addition to designing and creating molds, mold makers are also responsible for maintaining and repairing them. Over time, molds can wear out or become damaged due to the high pressures and temperatures involved in the injection molding process. Mold makers need to have the skills and knowledge to identify and fix any issues that may arise. Regular maintenance and repairs are crucial to ensure the longevity and performance of the molds, as well as the quality of the final products.

In conclusion, mold makers play a vital role in the plastic injection molding process. Their expertise and attention to detail are essential in designing and creating molds that produce high-quality plastic parts. They must consider various factors, such as material flow and cooling, to ensure the molds meet the specific requirements of each project. Additionally, mold makers are responsible for maintaining and repairing the molds to ensure their longevity and performance. Without skilled mold makers, the plastic injection molding process would not be as efficient or successful.