The Basics of Molding Injection Plastic Moulds

Molding injection plastic molds are an essential tool in the manufacturing industry. They play a crucial role in creating various plastic products that we use in our daily lives. In this article, we will delve into the basics of molding injection plastic molds, exploring their purpose, the materials used, and the process involved.

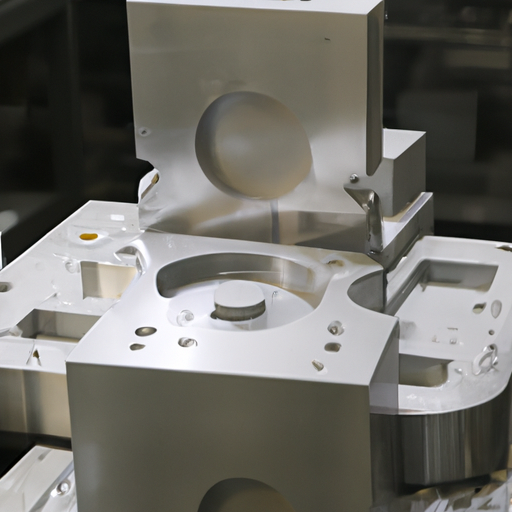

Firstly, let’s understand the purpose of molding injection plastic molds. These molds are used to shape molten plastic into a desired form. They are typically made from steel or aluminum and consist of two halves, known as the mold cavity and the mold core. The mold cavity is where the plastic is injected, while the mold core helps to shape the final product. These molds are designed to be reusable, allowing for mass production of plastic products.

Now, let’s discuss the materials used in molding injection plastic molds. As mentioned earlier, steel and aluminum are the most common materials used due to their durability and heat resistance. Steel molds are preferred for high-volume production as they can withstand the repeated stress of the injection process. On the other hand, aluminum molds are suitable for low-volume production or prototyping due to their lower cost and faster cooling time.

Moving on, let’s explore the process of molding injection plastic molds. It begins with the design of the mold, which involves creating a 3D model using computer-aided design (CAD) software. This model is then used to create a mold prototype, which is tested for functionality and accuracy. Once the prototype is approved, the actual mold is manufactured using CNC machining or other precision techniques.

Once the mold is ready, the molding process begins. It starts with the plastic material being heated and melted into a liquid state. This molten plastic is then injected into the mold cavity under high pressure. The mold is kept closed until the plastic cools and solidifies, taking the shape of the mold cavity. After the cooling process, the mold is opened, and the final product is ejected.

| Product Name | our services |

| Plastic injection molding parts | one-stop services |

It is worth noting that the molding injection plastic mold process can be complex and requires skilled operators. The temperature, pressure, and cooling time must be carefully controlled to ensure the quality and consistency of the final product. Additionally, the mold may need to be cleaned and maintained regularly to prevent any defects or damage.

In conclusion, molding injection plastic molds are vital in the manufacturing industry for creating a wide range of plastic products. They are made from durable materials such as steel or aluminum and consist of a mold cavity and mold core. The process involves heating and injecting molten plastic into the mold, which then cools and solidifies to form the final product. It is a complex process that requires precision and expertise. With the basics of molding injection plastic molds covered, we can appreciate the importance of these molds in our everyday lives.