Table of Contents

The Benefits of Working with a Plastic Auto Parts Manufacturer

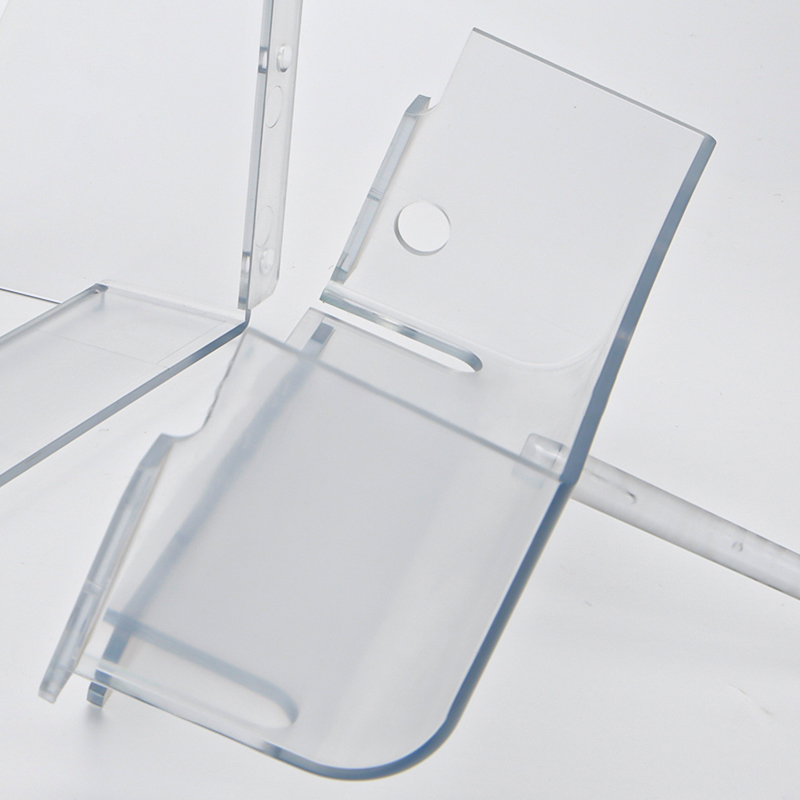

Working with a plastic auto parts manufacturer offers a number of benefits for businesses in the automotive industry. From cost savings to improved product quality, partnering with a plastic auto parts manufacturer can help businesses achieve their goals.

Cost Savings: Plastic auto parts are typically more cost-effective than metal parts, making them an attractive option for businesses looking to reduce costs. Plastic auto parts are also lighter than metal parts, which can help reduce shipping costs.

Improved Product Quality: Plastic auto parts are often more durable and reliable than metal parts, making them a great choice for businesses looking to improve the quality of their products. Plastic auto parts are also more resistant to corrosion and wear and tear, making them a great choice for businesses looking to extend the life of their products.

Faster Production Times: Plastic auto parts can be produced faster than metal parts, making them a great choice for businesses looking to reduce production times. Plastic auto parts are also easier to mold and shape, making them a great choice for businesses looking to create custom parts.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

Environmental Benefits: Plastic auto parts are often more environmentally friendly than metal parts, making them a great choice for businesses looking to reduce their environmental impact. Plastic auto parts are also recyclable, making them a great choice for businesses looking to reduce their waste.

Overall, working with a plastic auto parts manufacturer offers a number of benefits for businesses in the automotive industry. From cost savings to improved product quality, partnering with a plastic auto parts manufacturer can help businesses achieve their goals.