The Process of Plastic Clip Injection Molding

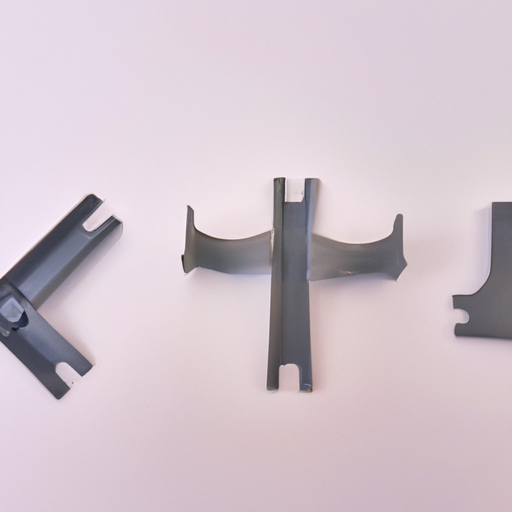

Plastic clip injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create plastic clips. These clips are used in various industries, including automotive, electronics, and packaging. The process of plastic clip injection molding is complex and requires precision and expertise.

The first step in plastic clip injection molding is the design of the mold. The mold is typically made of steel and consists of two halves, the cavity, and the core. The design of the mold is crucial as it determines the final shape and dimensions of the plastic clip. Computer-aided design (CAD) software is often used to create the mold design, ensuring accuracy and efficiency.

Once the mold design is finalized, the next step is the fabrication of the mold. This involves machining the steel blocks to create the cavity and core. The machining process requires high precision to ensure that the mold is accurate and can produce high-quality plastic clips. After the machining process, the mold is polished to achieve a smooth surface finish, which is essential for the final product.

After the mold fabrication, the mold is mounted onto an injection molding machine. The machine consists of a hopper, where the plastic material is loaded, and a heating unit, which melts the plastic into a molten state. The molten plastic is then injected into the mold cavity under high pressure. The pressure ensures that the plastic fills the entire cavity and takes the shape of the mold.

Once the plastic is injected into the mold, it is left to cool and solidify. The cooling process is crucial as it determines the final strength and stability of the plastic clip. Cooling can be achieved through various methods, such as air cooling or water cooling. The cooling time depends on the type of plastic used and the size and complexity of the clip.

After the plastic has cooled and solidified, the mold is opened, and the plastic clip is ejected. The ejection process can be automated or manual, depending on the complexity of the mold and the clip. The ejected clips are then inspected for any defects or imperfections. Quality control measures, such as visual inspection or automated systems, are used to ensure that only high-quality clips are produced.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

The process of plastic clip injection molding offers several advantages. Firstly, it allows for the production of complex shapes and intricate designs that would be difficult or impossible to achieve with other manufacturing processes. Secondly, it offers high production efficiency, as multiple clips can be produced simultaneously using multi-cavity molds. Lastly, it provides excellent repeatability, ensuring consistent quality and dimensions for each plastic clip.

In conclusion, plastic clip injection molding is a complex and precise manufacturing process that involves the injection of molten plastic into a mold to create plastic clips. The process requires careful design and fabrication of the mold, as well as the use of advanced machinery and quality control measures. Plastic clip injection molding offers numerous advantages, making it a popular choice for the production of plastic clips in various industries.