The Benefits of Using Plastic CNC Milled Parts in Manufacturing

Using plastic CNC milled parts in manufacturing can be a great way to save time and money. CNC milled parts are made with precision and accuracy, meaning that they are more reliable and durable than parts made with traditional manufacturing methods. Additionally, CNC milled parts are often more cost-effective than other methods, as they require less labor and materials.

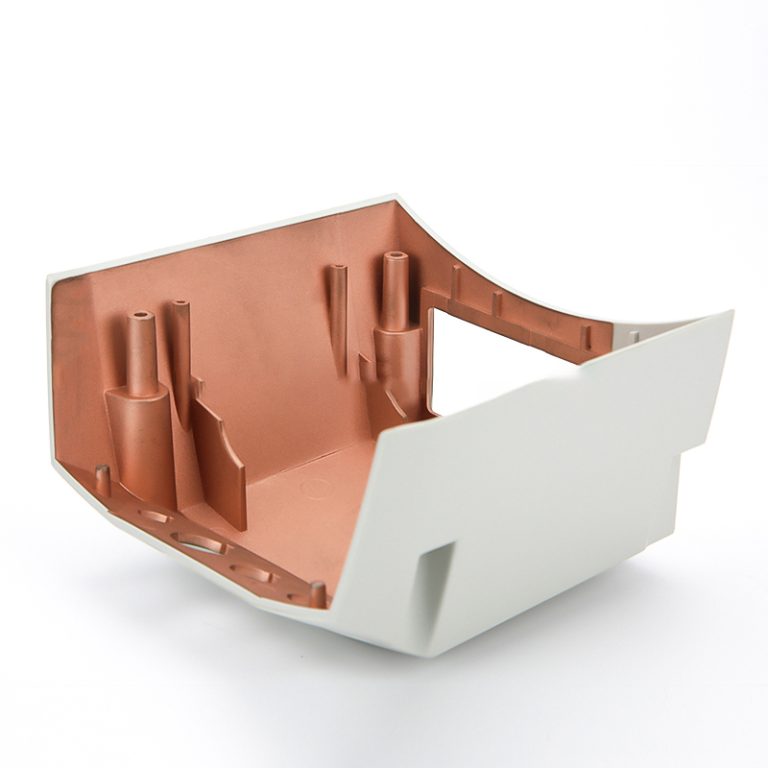

The precision of CNC milled parts also makes them ideal for use in a variety of applications. For example, they can be used to create intricate shapes and designs that would be difficult to achieve with traditional manufacturing methods. This makes them perfect for creating complex parts for medical devices, aerospace components, and other precision-critical applications.

CNC milled parts are also more efficient than traditional manufacturing methods. They can be produced quickly and with minimal waste, meaning that they can be used to create parts faster and with less cost. This makes them ideal for use in high-volume production runs, where speed and efficiency are essential.

Finally, CNC milled parts are also more environmentally friendly than traditional manufacturing methods. They require fewer resources and produce less waste, meaning that they can help reduce the environmental impact of manufacturing. This makes them a great choice for companies looking to reduce their carbon footprint.

| Material selection | colour |

| PP/PC/ABS/PET/PEEK/ETC. | OEM/ODM |

Overall, using plastic CNC milled parts in manufacturing can be a great way to save time and money while also reducing the environmental impact of production. They are precise, efficient, and cost-effective, making them an ideal choice for a variety of applications.