Benefits of Using Plastic Injection Molding Conveyor Belts in Manufacturing Processes

Plastic injection molding conveyor belts have become an essential component in the manufacturing industry, offering a wide range of benefits that contribute to increased efficiency and productivity. These conveyor belts are designed to transport materials throughout the production process, ensuring a smooth and continuous flow of operations. In this article, we will explore the various advantages of using plastic injection molding conveyor belts in manufacturing processes.

One of the key benefits of plastic injection molding conveyor belts is their ability to streamline the production process. By automating the movement of materials from one stage to the next, these conveyor belts eliminate the need for manual handling, reducing the risk of errors and increasing overall efficiency. This not only saves time but also minimizes the likelihood of product defects, ultimately leading to higher quality output.

In addition to improving efficiency, plastic injection molding conveyor belts also help to optimize space within the manufacturing facility. By utilizing vertical and horizontal configurations, these conveyor belts can be customized to fit the layout of the production floor, maximizing the use of available space. This allows manufacturers to increase their output without the need for additional square footage, ultimately reducing operational costs and improving profitability.

Furthermore, plastic injection molding conveyor belts are designed to enhance worker safety in the manufacturing environment. By automating the movement of materials, these conveyor belts reduce the need for manual lifting and carrying, minimizing the risk of workplace injuries. This not only creates a safer working environment but also boosts employee morale and productivity, as workers can focus on more skilled tasks rather than manual labor.

Another advantage of using plastic injection molding conveyor belts is their versatility and adaptability to different production requirements. These conveyor belts can be customized to accommodate various types of materials, shapes, and sizes, making them suitable for a wide range of manufacturing processes. Whether handling small components or large assemblies, plastic injection molding conveyor belts can be tailored to meet the specific needs of each production line.

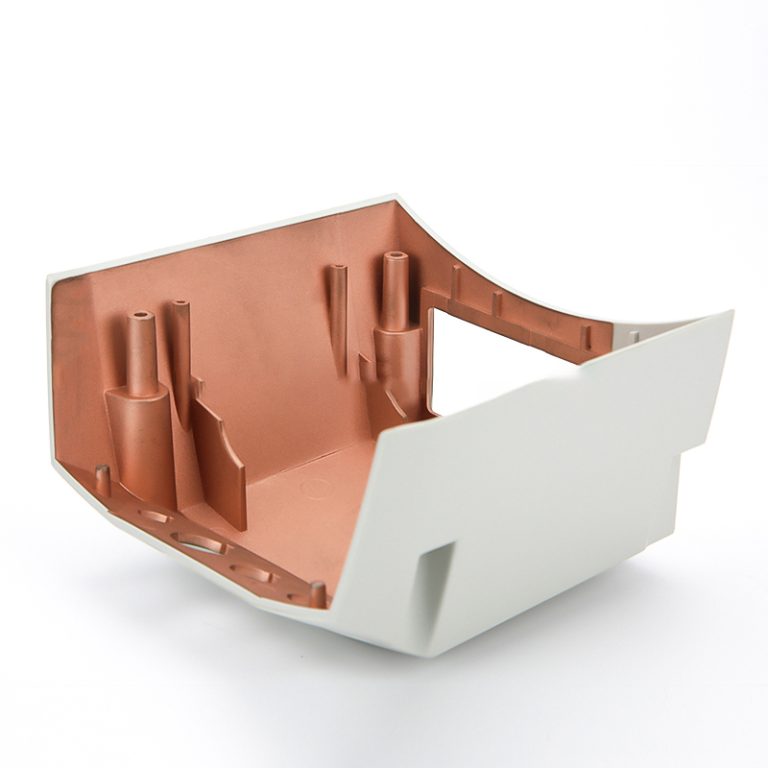

Moreover, plastic injection molding conveyor belts are designed to be durable and long-lasting, providing a reliable solution for continuous operation in the manufacturing industry. Made from high-quality materials, these conveyor belts are resistant to wear and tear, ensuring minimal downtime and maintenance costs. This reliability allows manufacturers to focus on their core business activities without worrying about equipment failures or disruptions in the production process.

| Product Name | our services |

| Plastic injection molding parts | one-stop services |

In conclusion, plastic injection molding conveyor belts offer a multitude of benefits for manufacturers looking to improve efficiency, productivity, and safety in their production processes. By automating material handling, optimizing space, enhancing worker safety, and providing versatility and durability, these conveyor belts play a crucial role in streamlining operations and maximizing output. As the manufacturing industry continues to evolve, plastic injection molding conveyor belts will remain a valuable asset for companies seeking to stay competitive in a fast-paced and demanding market.