Benefits of Custom Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process allows for the production of a wide range of plastic parts and products with high precision and efficiency. Custom plastic injection molding takes this process a step further by offering tailored solutions to meet specific design requirements and production needs.

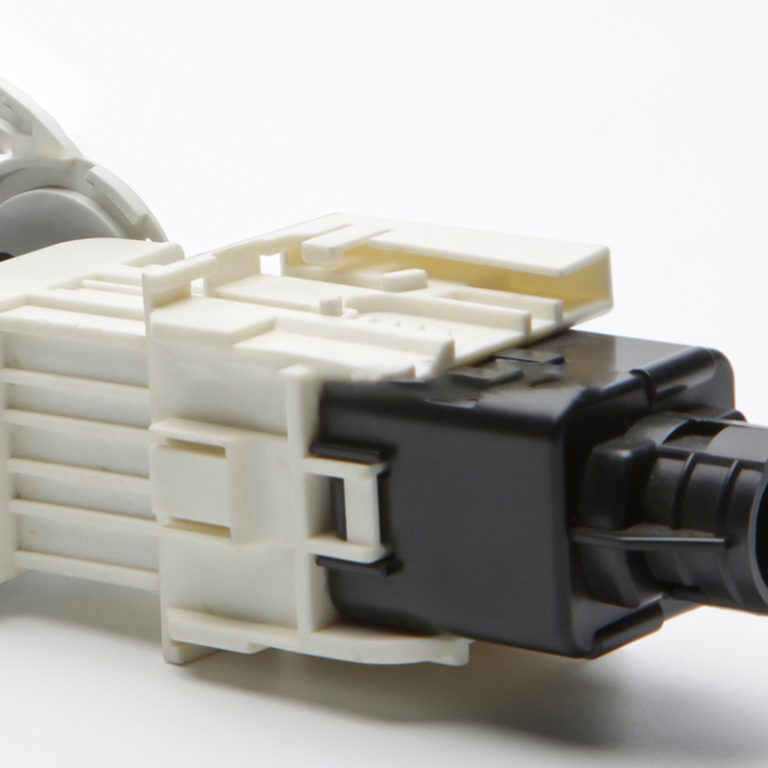

One of the key benefits of custom plastic injection molding is the ability to create complex and intricate designs that may not be possible with other manufacturing methods. This is achieved through the use of advanced mold design and tooling techniques that allow for the production of parts with tight tolerances and intricate features. Custom plastic injection molding also offers the flexibility to produce parts in a wide range of sizes, shapes, and materials, making it a versatile solution for a variety of industries and applications.

Another advantage of custom plastic injection molding is the cost-effectiveness of producing high volumes of parts. The process is highly automated and can produce large quantities of parts in a short amount of time, reducing production costs and lead times. This makes custom plastic injection molding an ideal solution for mass production of plastic parts and products, allowing for economies of scale and competitive pricing.

Custom plastic injection molding also offers the benefit of consistency and repeatability in part production. The use of advanced molding techniques and quality control measures ensures that each part produced meets the specified design requirements and quality standards. This level of consistency is essential for industries that require precision and reliability in their products, such as the automotive, medical, and electronics industries.

In addition to precision and consistency, custom plastic injection molding also offers the advantage of design flexibility. The process allows for the incorporation of various features and functionalities into the part design, such as undercuts, threads, and inserts, without the need for secondary operations. This flexibility in design allows for the creation of complex and innovative products that meet the unique needs of customers and end-users.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

Custom plastic injection molding also provides the benefit of material selection, allowing for the use of a wide range of thermoplastic and thermoset materials to meet specific performance requirements. This includes materials with different properties, such as strength, flexibility, heat resistance, and chemical resistance, to ensure that the final product meets the desired specifications and performance criteria.

Overall, custom plastic injection molding offers a range of benefits that make it a preferred manufacturing process for producing high-quality plastic parts and products. From complex designs and cost-effective production to consistency and design flexibility, custom plastic injection molding provides a versatile and efficient solution for a variety of industries and applications. Whether you need to produce a small batch of custom parts or mass-produce a high volume of products, custom plastic injection molding can meet your production needs and deliver high-quality results.