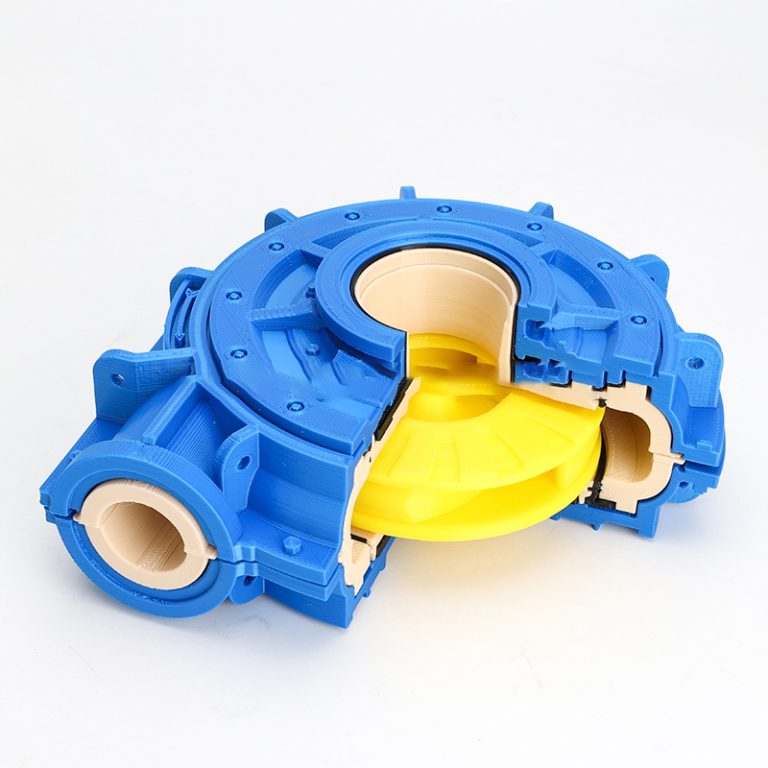

The Benefits of Using High-Quality Plastic Injection Molding Machine Parts

When it comes to plastic injection molding, the quality of the machine parts used is of the utmost importance. High-quality plastic injection molding machine parts can make the difference between a successful production run and a failed one. Here are some of the benefits of using high-quality plastic injection molding machine parts:

1. Durability: High-quality plastic injection molding machine parts are designed to last. They are made from strong, durable materials that can withstand the rigors of the injection molding process. This means that you won’t have to worry about replacing parts as often, saving you time and money in the long run.

2. Precision: High-quality plastic injection molding machine parts are designed to be precise. This means that the parts will fit together perfectly, ensuring that the finished product is of the highest quality.

3. Efficiency: High-quality plastic injection molding machine parts are designed to be efficient. This means that they will help to reduce the amount of time and energy needed to complete a production run. This can help to increase productivity and reduce costs.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

4. Safety: High-quality plastic injection molding machine parts are designed to be safe. This means that they will help to reduce the risk of accidents and injuries in the workplace.

Using high-quality plastic injection molding machine parts can help to ensure that your production runs are successful and that your products are of the highest quality. Investing in high-quality parts can help to save you time and money in the long run.