Table of Contents

Exploring the Benefits of Plastic Injection Molding for Medical Parts

The Latest Innovations in Plastic Injection Molding for Medical Parts

Table of Contents

It sounds like you’re interested in services related to prototyping and custom aluminum models. Here are some points to consider and some information that might be helpful: 1.Prototyping Services: Many companies specialize in prototyping various types of products, including those made from aluminum. These services cater to individuals and businesses looking to create prototypes for…

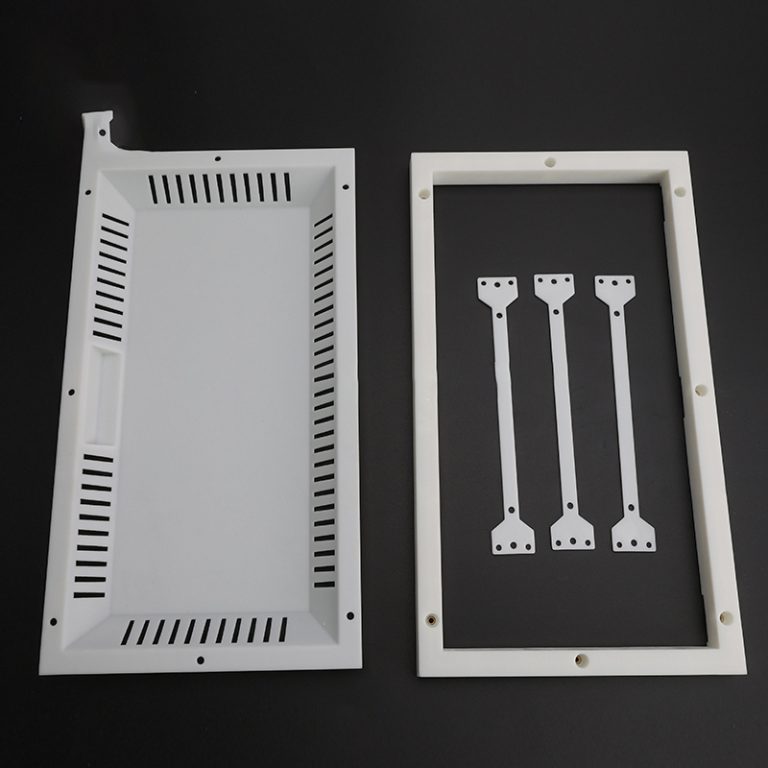

How Custom Plastic Parts Injection Molding Can Help Your Business Custom plastic parts injection molding is a great way to help your business succeed. It is a cost-effective and efficient way to produce high-quality parts that are tailored to your exact specifications. With custom plastic parts injection molding, you can create parts that are designed…

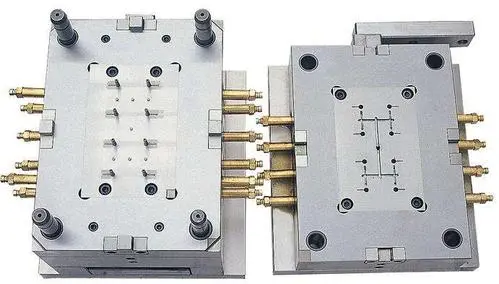

The Benefits of Injection Molded Plastic Parts for Manufacturing Applications Injection molded plastic parts are a popular choice for manufacturing applications due to their many benefits. Injection molding is a process that involves injecting molten plastic into a mold to create a part with a specific shape and size. This process is highly efficient and…

Structural foam spray insulation, also known as structural foam or spray foam insulation, is a type of insulation material commonly used in construction and building applications. It’s distinct from traditional insulation materials like fiberglass or cellulose due to its application method and unique properties.Application Method:Structural foam insulation is typically applied as a liquid using specialized…

The Benefits of Using High-Quality Plastic Injection Molding Machine Parts When it comes to plastic injection molding, the quality of the machine parts used is of the utmost importance. High-quality plastic injection molding machine parts can make the difference between a successful production run and a failed one. Here are some of the benefits of…

Top 10 Plastic Injection Molding Companies in the Industry Plastic injection molding is a widely used manufacturing process in which molten plastic is injected into a mold to create various plastic products. This process is highly efficient and cost-effective, making it a popular choice for many industries. However, finding the right plastic injection molding company…