The Benefits of Using Plastic Injection Molding Trays in Manufacturing Processes

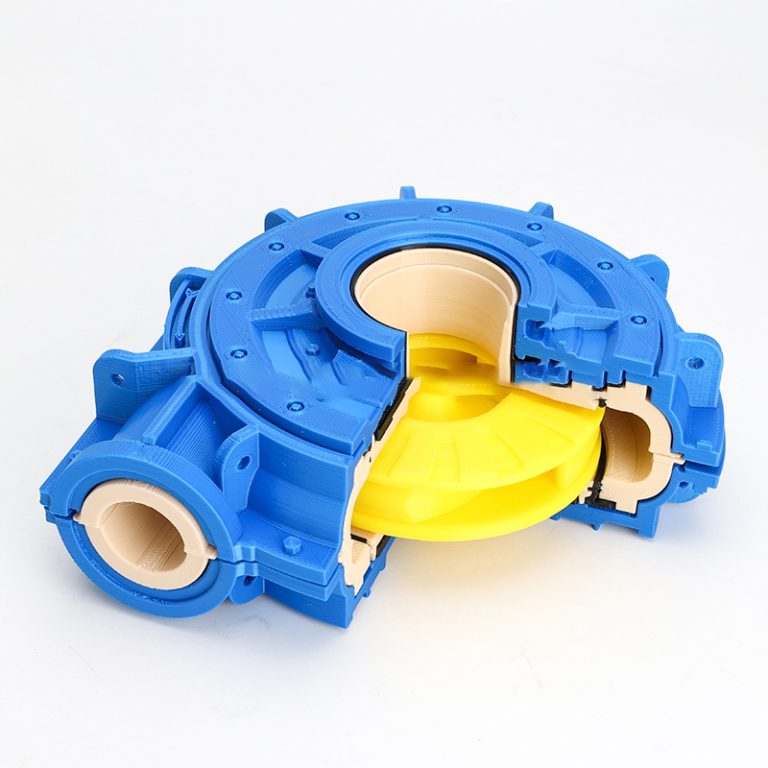

Plastic injection molding trays have become an essential tool in the manufacturing industry. These trays are used to hold and transport various components during the production process. They are made through a process called plastic injection molding, which involves injecting molten plastic into a mold cavity. Once the plastic cools and solidifies, it takes the shape of the mold, resulting in a durable and reliable tray.

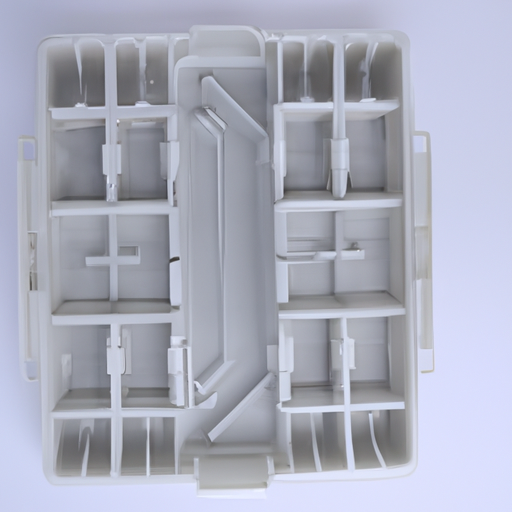

One of the main benefits of using plastic injection molding trays is their versatility. These trays can be customized to fit the specific needs of different manufacturing processes. They can be designed with various compartments and slots to securely hold and organize components. This helps to prevent damage and loss of parts, ensuring a smooth and efficient production line.

Another advantage of plastic injection molding trays is their durability. These trays are made from high-quality plastics that are resistant to wear and tear. They can withstand the rigors of daily use in a manufacturing environment without losing their shape or functionality. This durability translates into cost savings for manufacturers, as they do not have to constantly replace worn-out trays.

Plastic injection molding trays are also lightweight, making them easy to handle and transport. This is particularly important in industries where components need to be moved quickly and efficiently. The lightweight nature of these trays reduces the risk of strain injuries for workers and allows for faster production cycles.

| Material selection | colour |

| PP/PC/ABS/PET/PEEK/ETC. | OEM/ODM |

In addition to their versatility, durability, and lightweight design, plastic injection molding trays offer excellent protection for components. These trays are designed to securely hold parts in place, preventing them from shifting or colliding during transportation. This reduces the risk of damage and ensures that components arrive at their destination in perfect condition.

Furthermore, plastic injection molding trays are easy to clean and maintain. They can be quickly wiped down or washed, ensuring that they remain free from dirt, dust, and other contaminants. This is crucial in industries where cleanliness is paramount, such as the medical and food sectors.

Plastic injection molding trays also contribute to sustainability efforts. They are made from recyclable materials, which can be melted down and reused to create new trays or other plastic products. This helps to reduce waste and minimize the environmental impact of manufacturing processes.

In conclusion, plastic injection molding trays offer numerous benefits in manufacturing processes. Their versatility, durability, lightweight design, and excellent protection capabilities make them an indispensable tool for many industries. Additionally, their ease of cleaning and maintenance, as well as their contribution to sustainability efforts, further enhance their appeal. As the manufacturing industry continues to evolve, plastic injection molding trays will undoubtedly play a crucial role in ensuring efficient and sustainable production processes.