Table of Contents

The Benefits of Plastic Injection Moulded Parts for Manufacturing

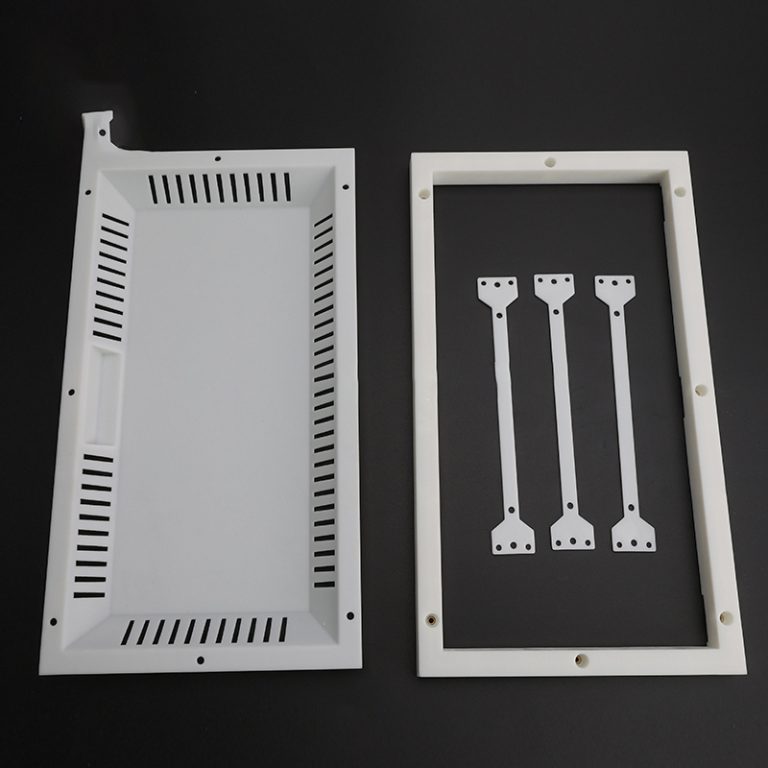

Plastic injection moulded parts are becoming increasingly popular in the manufacturing industry due to their many benefits. Compared to traditional manufacturing methods, plastic injection moulding offers a number of advantages that make it the preferred choice for many manufacturers.

First, plastic injection moulding is a cost-effective solution. The process is highly automated, which reduces labour costs and increases efficiency. Additionally, the moulds used in the process are relatively inexpensive and can be reused multiple times, further reducing costs.

Second, plastic injection moulding is a fast and efficient process. The process is highly automated, which means that parts can be produced quickly and with minimal human intervention. This makes it ideal for high-volume production runs.

| Product Name | colour |

| Plastic injection molding parts | OEM/ODM |

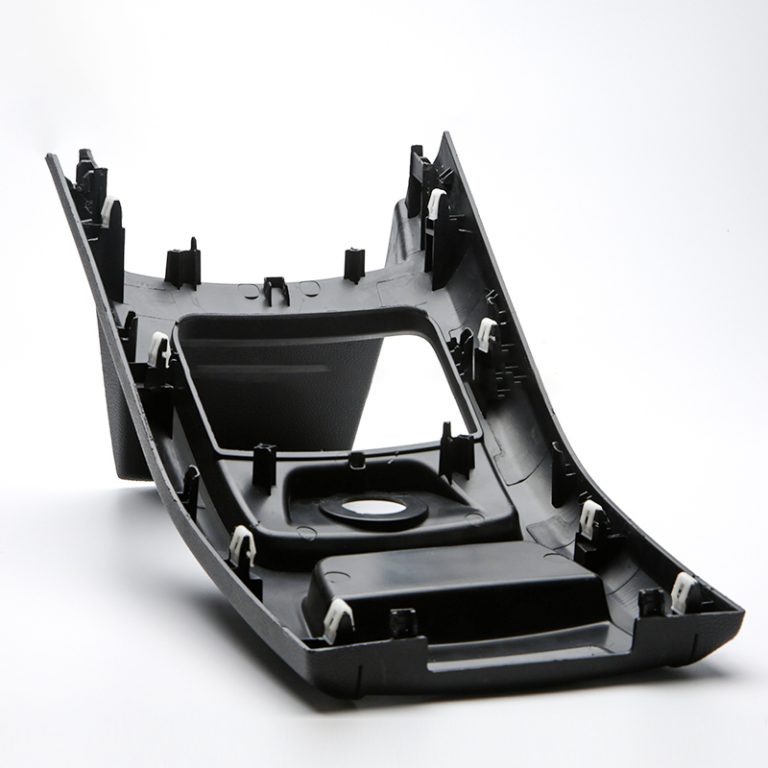

Third, plastic injection moulding is a precise process. The moulds used in the process are highly accurate, which means that parts produced are of a consistent quality. This makes it ideal for producing parts with complex shapes and intricate details.

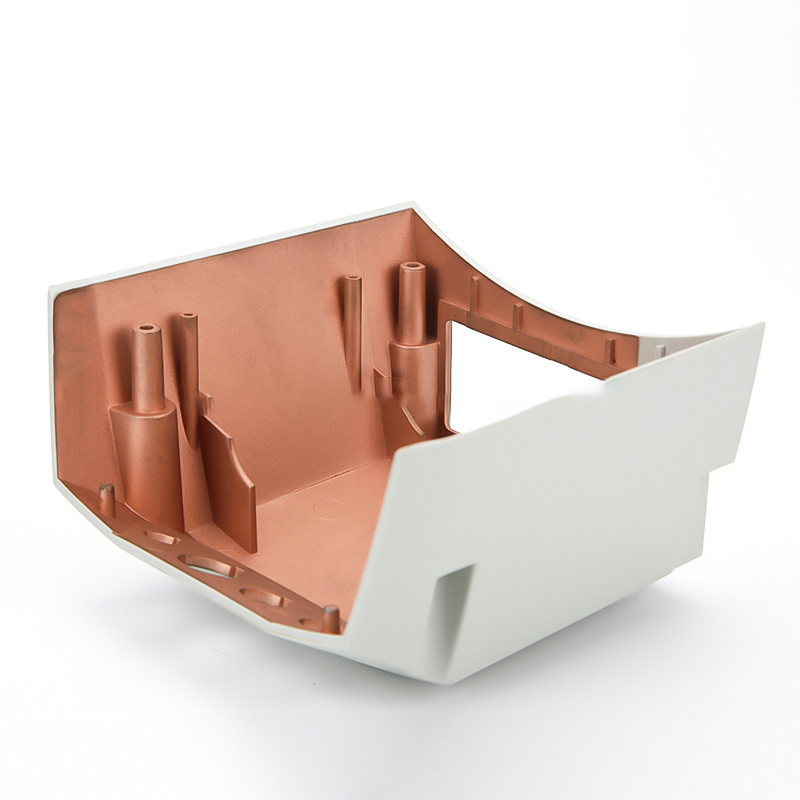

Finally, plastic injection moulding is a versatile process. It can be used to produce parts in a wide range of materials, including thermoplastics, thermosets, and elastomers. This makes it ideal for producing parts for a variety of applications.

Overall, plastic injection moulding is an ideal solution for manufacturers looking for a cost-effective, efficient, precise, and versatile manufacturing process. With its many benefits, it is no wonder that plastic injection moulding is becoming increasingly popular in the manufacturing industry.

The Design Considerations for Creating Plastic Injection Moulded Parts

Creating plastic injection moulded parts is a complex process that requires careful consideration of a variety of design elements. From the material selection to the mould design, each step of the process must be carefully planned to ensure the highest quality product. Here are some of the key design considerations for creating plastic injection moulded parts:

Material Selection: The material selection is one of the most important design considerations for creating plastic injection moulded parts. Different materials have different properties, so it’s important to select the right material for the application. Factors such as strength, flexibility, and cost should all be taken into account when selecting the material.

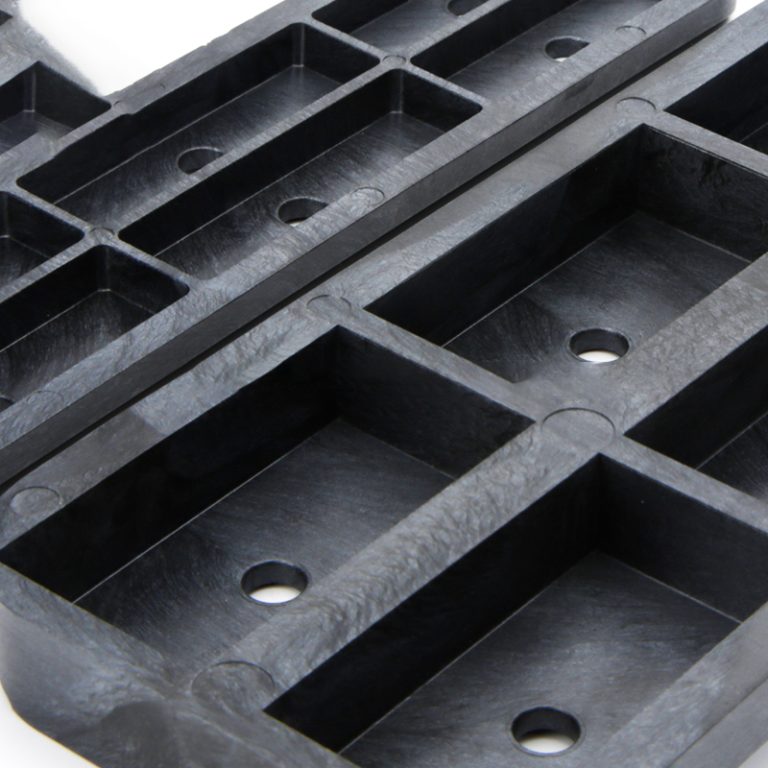

Mould Design: The mould design is another important consideration for creating plastic injection moulded parts. The mould must be designed to ensure that the part is produced with the desired shape and dimensions. The mould must also be designed to ensure that the part is produced with the desired surface finish.

Process Parameters: The process parameters must also be carefully considered when creating plastic injection moulded parts. The injection pressure, injection speed, and cooling time must all be carefully adjusted to ensure that the part is produced with the desired properties.

These are just a few of the design considerations for creating plastic injection moulded parts. By carefully considering each of these elements, you can ensure that your parts are produced with the highest quality and performance.