Table of Contents

Benefits of Using Plastic Mold Injection Molding for Mass Production

Plastic mold injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process is commonly used for mass production of plastic parts and products due to its efficiency, accuracy, and cost-effectiveness. There are several benefits to using plastic mold injection molding for mass production, which we will explore in this article.

| Material selection | colour |

| PP/PC/ABS/PET/PEEK/ETC. | OEM/ODM |

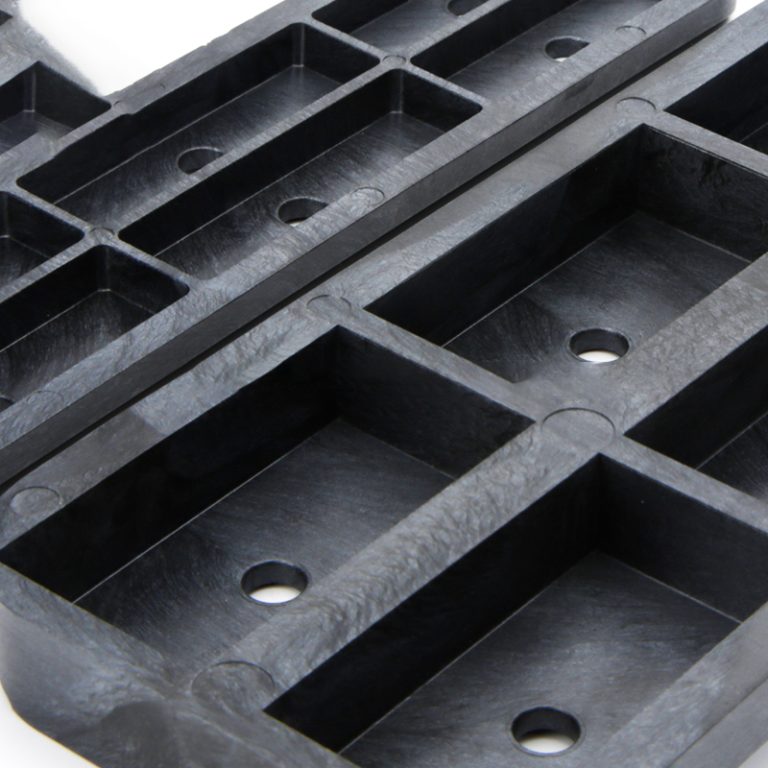

One of the key advantages of plastic mold injection molding is its ability to produce high volumes of identical parts with great precision and consistency. The molds used in this process are designed to exact specifications, ensuring that each part produced is identical to the next. This level of precision is essential for industries that require consistent quality and performance in their products.

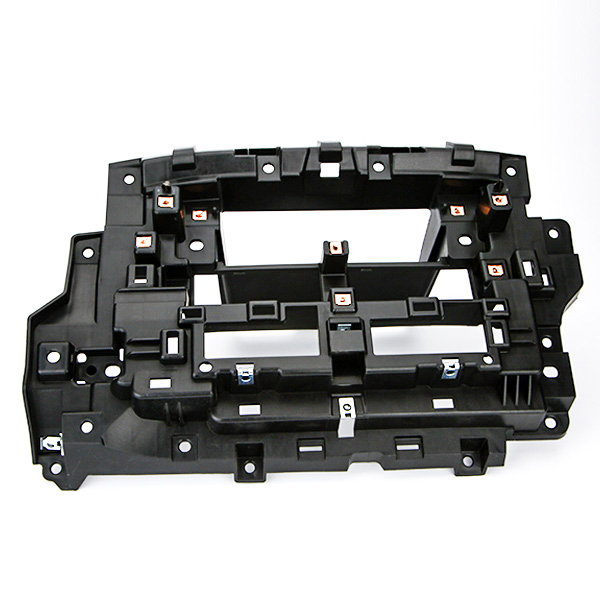

Another benefit of plastic mold injection molding is its efficiency in producing complex shapes and intricate details. The mold cavity can be designed with intricate features and details that would be difficult or impossible to achieve with other manufacturing processes. This makes plastic mold injection molding ideal for producing parts with complex geometries, such as gears, threads, and thin walls.

In addition to its precision and complexity, plastic mold injection molding is also a cost-effective manufacturing process for mass production. Once the mold is created, the cost per part decreases significantly as the production volume increases. This makes plastic mold injection molding a cost-effective solution for producing large quantities of plastic parts and products.

Furthermore, plastic mold injection molding is a fast and efficient process that can produce parts in a matter of seconds. The cycle time for each part is relatively short, allowing for high production rates and quick turnaround times. This makes plastic mold injection molding an ideal choice for industries that require fast production speeds and short lead times.

Additionally, plastic mold injection molding is a versatile process that can accommodate a wide range of plastic materials. Different types of plastics can be used in the injection molding process, each with its own unique properties and characteristics. This versatility allows manufacturers to choose the best material for their specific application, whether it be for strength, flexibility, heat resistance, or other properties.

Moreover, plastic mold injection molding is a sustainable manufacturing process that produces minimal waste. The excess plastic material that is generated during the molding process can be recycled and reused, reducing the overall environmental impact of production. This makes plastic mold injection molding a more environmentally friendly option compared to other manufacturing processes that generate more waste.

In conclusion, plastic mold injection molding offers numerous benefits for mass production, including precision, complexity, cost-effectiveness, efficiency, versatility, and sustainability. This manufacturing process is ideal for industries that require high volumes of identical parts with intricate details and fast production speeds. With its ability to produce high-quality parts at a low cost, plastic mold injection molding is a preferred choice for manufacturers looking to streamline their production processes and deliver consistent, high-quality products to their customers.

Common Challenges Faced in Plastic Mold Injection Molding Process

Plastic mold injection molding is a widely used manufacturing process in which molten plastic is injected into a mold cavity to create a desired shape. While this process offers numerous benefits, such as high production efficiency and design flexibility, it also comes with its fair share of challenges. In this article, we will explore some of the common challenges faced in plastic mold injection molding and discuss potential solutions to overcome them.

One of the primary challenges in plastic mold injection molding is achieving uniform cooling throughout the mold cavity. Non-uniform cooling can result in uneven shrinkage of the plastic part, leading to warpage and dimensional inaccuracies. To address this issue, mold designers often incorporate cooling channels into the mold to ensure consistent cooling across the entire part. Additionally, optimizing the placement and design of these cooling channels can help improve cycle times and reduce production costs.

Another common challenge in plastic mold injection molding is the occurrence of sink marks on the surface of the molded part. Sink marks are depressions or dimples that form when the outer surface of the part cools and solidifies faster than the inner core. To minimize the risk of sink marks, mold designers can adjust the wall thickness of the part, use ribbing or gussets to reinforce thin sections, and optimize the gate location to ensure even filling of the mold cavity.

Inadequate venting is another challenge that can arise during the plastic mold injection molding process. Poor venting can lead to trapped air or gases in the mold cavity, resulting in surface defects such as burn marks, bubbles, or voids in the finished part. To prevent these issues, mold designers must carefully consider the placement and design of venting channels to allow for the escape of air and gases during the injection process. Regular maintenance and cleaning of the vents are also essential to ensure optimal mold performance.

Controlling the flow of molten plastic within the mold cavity is crucial for achieving high-quality parts in plastic mold injection molding. However, achieving proper flow control can be challenging, especially when molding complex geometries or thin-walled parts. To address this challenge, mold designers can use advanced simulation software to analyze and optimize the flow of plastic within the mold cavity. Additionally, adjusting the injection speed, pressure, and temperature can help improve flow control and reduce the risk of defects such as short shots or flash.

Maintaining consistent part quality and dimensional accuracy is a key challenge in plastic mold injection molding. Variations in material properties, processing conditions, and mold design can all impact the final part quality. To address this challenge, manufacturers must implement strict quality control measures, such as regular inspection and testing of parts, monitoring of process parameters, and calibration of equipment. Additionally, investing in high-quality materials and tooling can help ensure consistent part quality and reduce the risk of defects.

In conclusion, plastic mold injection molding offers numerous benefits for manufacturers, but it also comes with its fair share of challenges. By understanding and addressing these common challenges, manufacturers can optimize their molding processes, improve part quality, and reduce production costs. Through careful design, analysis, and optimization, manufacturers can overcome the challenges of plastic mold injection molding and achieve success in their manufacturing operations.