Table of Contents

The Benefits of Using Plastic Mold Parts for Your Manufacturing Process

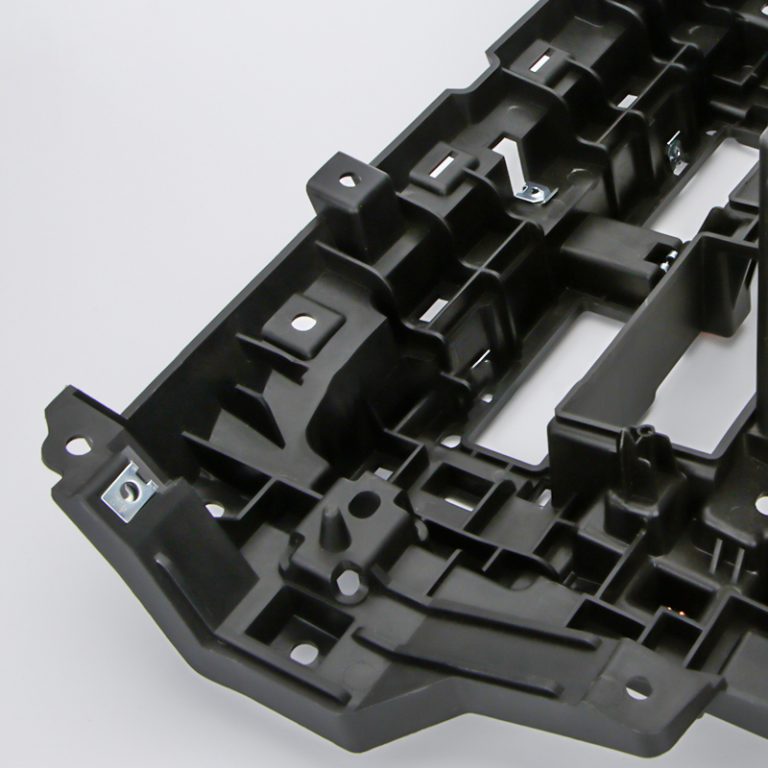

Plastic mold parts are an essential component of the manufacturing process for many industries. They are used to create a variety of products, from medical devices to automotive parts. Plastic mold parts offer a number of advantages over traditional metal parts, making them an ideal choice for many applications.

One of the primary benefits of using plastic mold parts is their cost-effectiveness. Plastic mold parts are typically much less expensive than metal parts, making them a great choice for companies looking to reduce costs. Additionally, plastic mold parts are often easier to produce than metal parts, which can help to reduce production time and costs.

Another advantage of plastic mold parts is their durability. Plastic mold parts are highly resistant to corrosion and wear, making them ideal for use in harsh environments. This makes them a great choice for applications that require long-term performance. Additionally, plastic mold parts are often lighter than metal parts, which can help to reduce shipping costs.

| Product Name | colour |

| Plastic injection molding parts | OEM/ODM |

Finally, plastic mold parts are often easier to customize than metal parts. This makes them a great choice for companies that need to produce parts with specific shapes or sizes. Additionally, plastic mold parts can be produced in a variety of colors, allowing companies to create products with unique designs.

Overall, plastic mold parts offer a number of advantages over traditional metal parts. They are cost-effective, durable, and easy to customize, making them an ideal choice for many manufacturing processes. By utilizing plastic mold parts, companies can reduce costs and create products with unique designs.

Exploring the Different Types of Plastic Mold Parts and Their Uses

Plastic mold parts are essential components of the plastic injection molding process. They are used to create a variety of products, from medical devices to consumer goods. In this article, we will explore the different types of plastic mold parts and their uses.

The first type of plastic mold part is the injection mold. This is the most common type of plastic mold part and is used to create a variety of products. The injection mold is made up of two halves that are clamped together and filled with molten plastic. The plastic is then injected into the mold cavity, where it cools and hardens into the desired shape. Injection molds are used to create a wide range of products, from medical devices to consumer goods.

The second type of plastic mold part is the blow mold. This type of mold is used to create hollow plastic parts, such as bottles and containers. The blow mold is made up of two halves that are clamped together and filled with molten plastic. The plastic is then injected into the mold cavity, where it is blown into the desired shape. Blow molds are used to create a wide range of products, from medical devices to consumer goods.

The third type of plastic mold part is the compression mold. This type of mold is used to create solid plastic parts, such as gears and bearings. The compression mold is made up of two halves that are clamped together and filled with molten plastic. The plastic is then injected into the mold cavity, where it is compressed into the desired shape. Compression molds are used to create a wide range of products, from medical devices to consumer goods.

Finally, the fourth type of plastic mold part is the transfer mold. This type of mold is used to create intricate plastic parts, such as circuit boards and connectors. The transfer mold is made up of two halves that are clamped together and filled with molten plastic. The plastic is then injected into the mold cavity, where it is transferred into the desired shape. Transfer molds are used to create a wide range of products, from medical devices to consumer goods.

In conclusion, there are four main types of plastic mold parts: injection molds, blow molds, compression molds, and transfer molds. Each type of mold is used to create a variety of products, from medical devices to consumer goods. Understanding the different types of plastic mold parts and their uses is essential for anyone involved in the plastic injection molding process.