Benefits of Using Plastic Molding Injection Parts in Manufacturing

Plastic molding injection parts have become a popular choice in the manufacturing industry due to their numerous benefits. From cost-effectiveness to design flexibility, these parts offer a wide range of advantages that make them an attractive option for many companies.

| Product Name | our services |

| Plastic injection molding parts | one-stop services |

One of the key benefits of using plastic molding injection parts is their cost-effectiveness. Compared to other manufacturing methods, such as machining or casting, plastic injection molding is often more affordable. This is because the process allows for high-volume production at a relatively low cost per unit. Additionally, the tooling costs for plastic molding injection parts are typically lower than those for other manufacturing methods, making it a cost-effective option for companies looking to produce large quantities of parts.

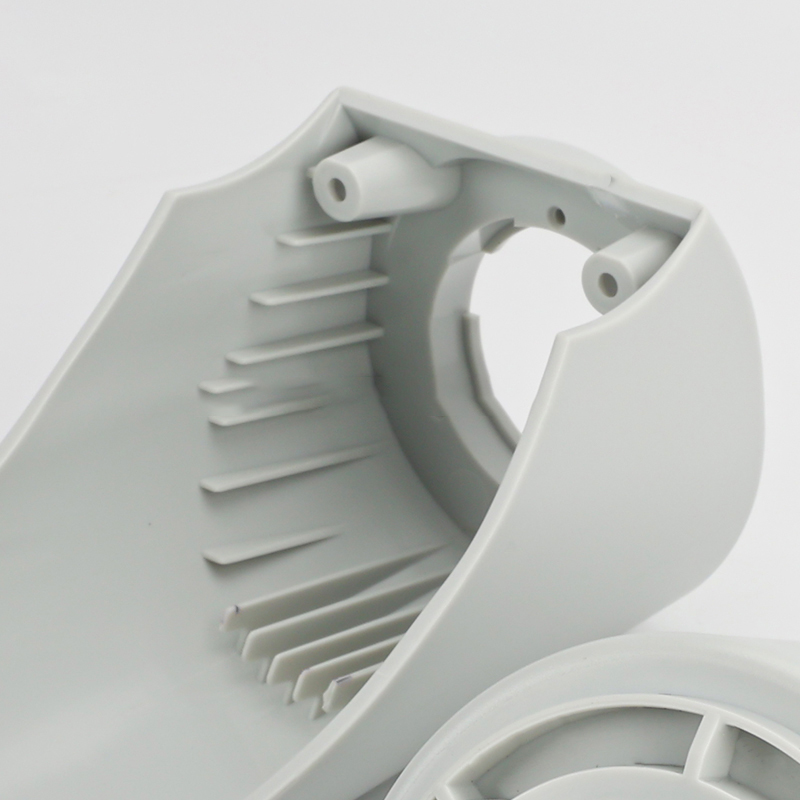

Another advantage of plastic molding injection parts is their design flexibility. The injection molding process allows for complex and intricate designs to be easily produced, making it ideal for parts that require intricate details or unique shapes. Additionally, plastic molding injection parts can be made in a wide range of sizes, from small, intricate components to large, complex parts. This versatility in design makes plastic molding injection parts a popular choice for companies looking to create custom parts that meet their specific requirements.

In addition to cost-effectiveness and design flexibility, plastic molding injection parts also offer durability and strength. Plastic injection molding produces parts that are strong and durable, making them suitable for a wide range of applications. Whether used in automotive, aerospace, medical, or consumer electronics industries, plastic molding injection parts can withstand the rigors of daily use and provide long-lasting performance.

Furthermore, plastic molding injection parts are lightweight, which can be advantageous in industries where weight is a critical factor. For example, in the automotive industry, lightweight parts can help improve fuel efficiency and overall performance. Additionally, the lightweight nature of plastic molding injection parts makes them easier to handle and transport, reducing shipping costs and logistics challenges.

Another benefit of using plastic molding injection parts is the ability to produce parts with consistent quality. The injection molding process allows for precise control over the production of parts, ensuring that each part meets the same high standards of quality. This consistency in quality is essential for companies looking to maintain a high level of product reliability and customer satisfaction.

Overall, plastic molding injection parts offer a wide range of benefits that make them an attractive option for companies in various industries. From cost-effectiveness to design flexibility, durability, and consistency in quality, plastic molding injection parts provide a reliable and efficient solution for manufacturing needs. Whether producing small, intricate components or large, complex parts, plastic molding injection parts offer a versatile and cost-effective option for companies looking to create high-quality products.