Table of Contents

The Benefits of Plastic Parts Injection Molding for Manufacturing

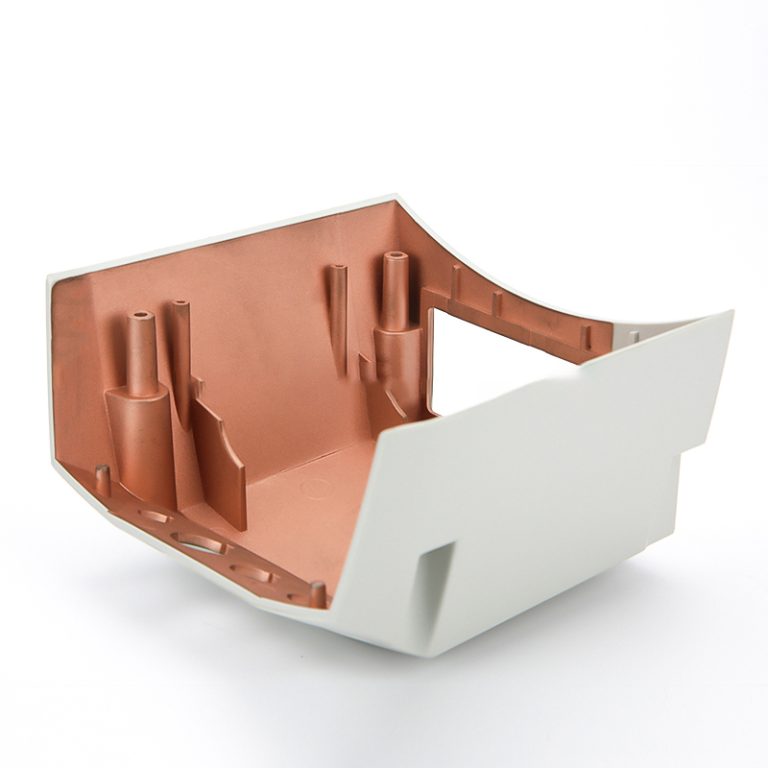

Plastic parts injection molding is a manufacturing process that has been used for decades to create a wide variety of products. This process is used to create parts from thermoplastic and thermoset materials, and it is a cost-effective and efficient way to produce high-quality parts in large quantities.

The injection molding process begins with a mold that is created from a CAD drawing or a prototype. The mold is then filled with molten plastic, which is injected into the mold under high pressure. The plastic is then cooled and the part is ejected from the mold.

| Material selection | colour |

| PP/PC/ABS/PET/PEEK/ETC. | OEM/ODM |

The benefits of plastic parts injection molding are numerous. It is a fast and efficient process that can produce parts with high accuracy and repeatability. The process is also cost-effective, as it requires minimal labor and can produce large quantities of parts quickly. Additionally, the process is highly customizable, allowing for the production of parts with complex shapes and intricate details.

Injection molding is also a very versatile process, as it can be used to create parts from a wide variety of materials. This includes thermoplastics, thermosets, and even elastomers. This versatility allows for the production of parts with different properties, such as strength, flexibility, and durability.

Finally, injection molding is a safe and environmentally friendly process. The process does not produce any hazardous waste, and the materials used are non-toxic and recyclable. This makes it an ideal choice for manufacturers who are looking to reduce their environmental impact.

Overall, plastic parts injection molding is a highly efficient and cost-effective manufacturing process that can be used to create a wide variety of parts with high accuracy and repeatability. It is also a safe and environmentally friendly process that can be used to create parts from a variety of materials. For these reasons, it is an ideal choice for manufacturers who are looking to produce high-quality parts in large quantities.

The Latest Innovations in Plastic Parts Injection Molding Technology

In recent years, the plastic parts injection molding industry has seen a number of exciting innovations that have revolutionized the way plastic parts are produced. These advancements have enabled manufacturers to produce parts with greater accuracy, precision, and speed than ever before.

One of the most significant innovations in plastic parts injection molding technology is the use of multi-axis robots. These robots are able to move in multiple directions, allowing them to precisely position the mold and inject the plastic into the mold with greater accuracy. This has enabled manufacturers to produce parts with greater precision and accuracy than ever before.

Another major advancement in plastic parts injection molding technology is the use of 3D printing. This technology allows manufacturers to create complex parts with intricate details that would otherwise be impossible to produce using traditional injection molding techniques. 3D printing also allows manufacturers to produce parts with greater speed and efficiency, as the entire process can be completed in a fraction of the time it would take to produce the same part using traditional methods.

Finally, the use of advanced software has enabled manufacturers to create parts with greater accuracy and precision than ever before. This software allows manufacturers to create detailed 3D models of the parts they are producing, which can then be used to create the molds for injection molding. This software also allows manufacturers to quickly and easily adjust the parameters of the injection molding process, allowing them to produce parts with greater accuracy and precision.

These advancements in plastic parts injection molding technology have revolutionized the way plastic parts are produced. Manufacturers are now able to produce parts with greater accuracy, precision, and speed than ever before, allowing them to create parts that are of higher quality and more cost-effective than ever before.