The Benefits of Using Plastic Pellets for Injection Molding

Plastic pellets are a versatile and cost-effective material that is commonly used in the injection molding process. Injection molding is a manufacturing process in which molten plastic is injected into a mold cavity, where it cools and hardens to form a desired shape. Plastic pellets are the raw material used in this process, and they offer a number of benefits that make them ideal for injection molding applications.

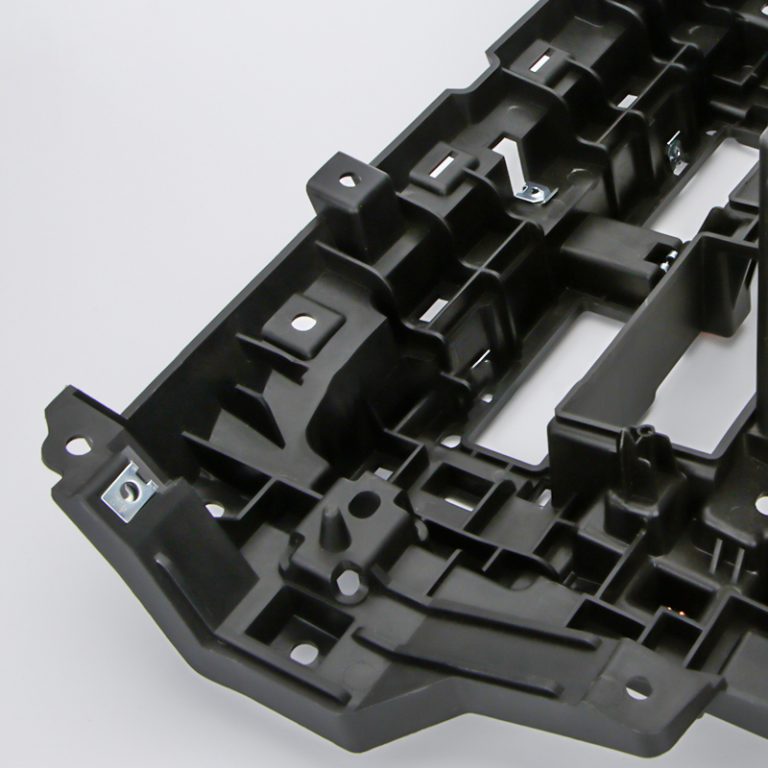

One of the key benefits of using plastic pellets for injection molding is their versatility. Plastic pellets come in a wide range of materials, colors, and additives, allowing manufacturers to create custom formulations that meet their specific requirements. This flexibility makes plastic pellets suitable for a variety of applications, from automotive parts to consumer products to medical devices.

In addition to their versatility, plastic pellets are also cost-effective. Because they can be easily melted and molded into shape, plastic pellets are an efficient material for mass production. This can help manufacturers reduce production costs and increase profitability. Furthermore, the ability to create custom formulations with plastic pellets can also lead to cost savings, as manufacturers can tailor the material to meet the exact specifications of their products.

Another benefit of using plastic pellets for injection molding is their durability. Plastic pellets are known for their strength and resilience, making them ideal for applications that require a high level of durability. This durability ensures that products made with plastic pellets will last longer and withstand the rigors of everyday use.

Furthermore, plastic pellets are also lightweight, which can be advantageous for certain applications. Lightweight materials can help reduce shipping costs and make products easier to handle and transport. This can be particularly beneficial for manufacturers who need to ship their products over long distances or who have strict weight restrictions.

In addition to their durability and lightweight properties, plastic pellets are also recyclable. Many plastic pellets are made from recycled materials, making them an environmentally friendly choice for manufacturers. By using recycled plastic pellets, manufacturers can reduce their carbon footprint and contribute to a more sustainable future.

Overall, the benefits of using plastic pellets for injection molding are clear. Their versatility, cost-effectiveness, durability, lightweight properties, and recyclability make them an ideal material for a wide range of applications. Whether you are manufacturing automotive parts, consumer products, or medical devices, plastic pellets offer a number of advantages that can help you create high-quality products at a competitive price.

| Material selection | size |

| ABS/PET/PEEK/ETC. | customization |

In conclusion, plastic pellets are a valuable material for injection molding applications. Their versatility, cost-effectiveness, durability, lightweight properties, and recyclability make them an ideal choice for manufacturers looking to create high-quality products that meet their specific requirements. By using plastic pellets for injection molding, manufacturers can benefit from a material that offers a wide range of advantages and helps them achieve their production goals.