Table of Contents

Benefits of Small Plastic Injection Molding for Prototyping

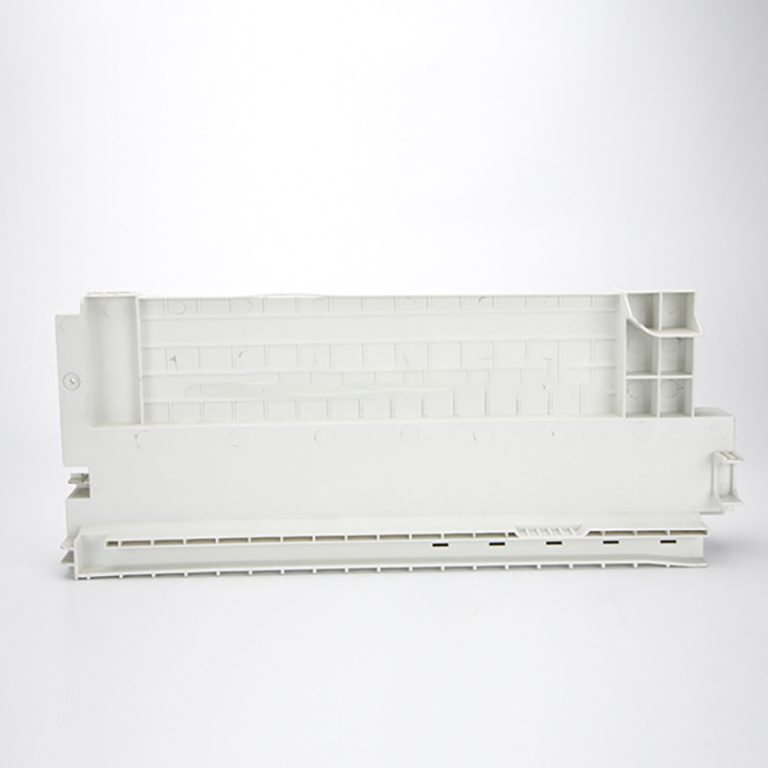

Small plastic injection molding is a versatile and cost-effective method for producing plastic parts in small quantities. This process involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. Small plastic injection molding is commonly used for prototyping, as it allows for quick and efficient production of small batches of parts for testing and evaluation.

One of the key benefits of small plastic injection molding for prototyping is its speed. Traditional manufacturing methods, such as machining or casting, can be time-consuming and expensive, especially for small quantities of parts. With small plastic injection molding, parts can be produced in a matter of days, allowing for rapid iteration and refinement of designs. This quick turnaround time is essential for companies looking to bring new products to market quickly and efficiently.

In addition to speed, small plastic injection molding offers a high level of precision and repeatability. The molds used in the injection molding process are typically made from steel or aluminum, which allows for tight tolerances and consistent part quality. This level of precision is crucial for prototyping, as it ensures that parts are produced accurately and consistently, allowing for accurate testing and evaluation of designs.

| Product Name | colour |

| Plastic injection molding parts | OEM/ODM |

Another benefit of small plastic injection molding for prototyping is its cost-effectiveness. While the initial tooling costs for injection molding can be high, especially for complex molds, the per-part cost decreases significantly as the quantity of parts produced increases. This makes small plastic injection molding an ideal choice for prototyping, as it allows for the production of small batches of parts at a relatively low cost. This cost-effectiveness is particularly important for companies with limited budgets or those looking to test multiple design iterations.

Small plastic injection molding also offers a wide range of material options, allowing for the production of parts with varying properties and characteristics. This flexibility is essential for prototyping, as it allows designers to test different materials and formulations to determine the best fit for their application. From rigid plastics like ABS and polycarbonate to flexible materials like TPE and TPU, small plastic injection molding can accommodate a wide range of material requirements.

Furthermore, small plastic injection molding is a scalable process, making it suitable for both small and large production runs. Once the initial tooling is created, parts can be produced quickly and efficiently, making it easy to ramp up production as needed. This scalability is important for companies looking to transition from prototyping to full-scale production, as it allows for a seamless transition from small batches to larger quantities.

In conclusion, small plastic injection molding offers a range of benefits for prototyping, including speed, precision, cost-effectiveness, material flexibility, and scalability. This versatile and efficient process is ideal for companies looking to quickly and cost-effectively produce small quantities of parts for testing and evaluation. Whether you are a startup looking to bring a new product to market or an established company looking to refine an existing design, small plastic injection molding is a valuable tool for prototyping.

Tips for Choosing the Right Small Plastic Injection Molding Machine

Small plastic injection molding machines are essential tools for businesses looking to produce small plastic parts efficiently and cost-effectively. With the right machine, companies can create high-quality products with precision and consistency. However, choosing the right small plastic injection molding machine can be a daunting task, as there are many factors to consider. In this article, we will provide some tips to help you select the best machine for your needs.

One of the first things to consider when choosing a small plastic injection molding machine is the size of the machine. The size of the machine will depend on the size of the parts you plan to produce. If you are looking to produce small parts, a smaller machine may be sufficient. However, if you plan to produce larger parts, you will need a larger machine. It is important to choose a machine that can accommodate the size of the parts you plan to produce.

Another important factor to consider when choosing a small plastic injection molding machine is the type of plastic material you plan to use. Different machines are designed to work with different types of plastic materials, so it is important to choose a machine that is compatible with the material you plan to use. Some machines are designed to work with a wide range of materials, while others are designed to work with specific types of materials. It is important to choose a machine that is compatible with the material you plan to use to ensure the best results.

In addition to the size and type of material, it is also important to consider the features and capabilities of the machine. Some machines come with advanced features such as computerized controls, automatic material feeding, and temperature control. These features can help improve the efficiency and quality of the molding process. It is important to choose a machine that has the features you need to produce high-quality parts efficiently.

When choosing a small plastic injection molding machine, it is also important to consider the cost of the machine. Small plastic injection molding machines can vary widely in price, so it is important to set a budget and stick to it. It is important to consider not only the initial cost of the machine but also the cost of maintenance and operation. It is important to choose a machine that fits within your budget while still meeting your production needs.

Finally, it is important to consider the reputation of the manufacturer when choosing a small plastic injection molding machine. It is important to choose a machine from a reputable manufacturer with a track record of producing high-quality machines. A machine from a reputable manufacturer is more likely to be reliable and durable, ensuring that you get the most out of your investment.

In conclusion, choosing the right small plastic injection molding machine is essential for businesses looking to produce small plastic parts efficiently and cost-effectively. By considering factors such as size, material compatibility, features, cost, and manufacturer reputation, you can select the best machine for your needs. With the right machine, you can produce high-quality parts with precision and consistency, helping your business succeed in today’s competitive market.