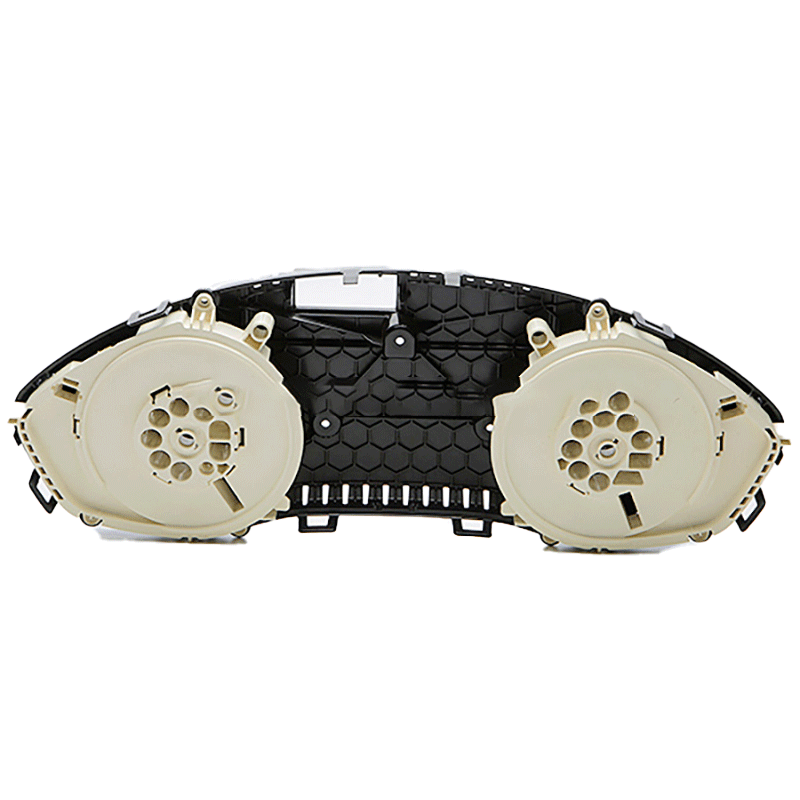

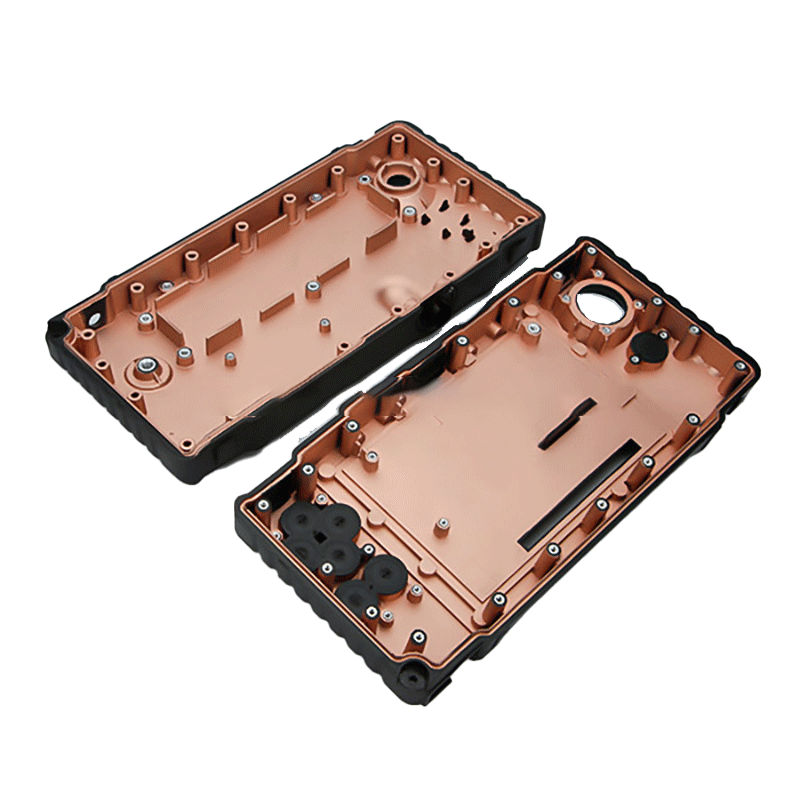

Injection Molding Service

Engineering-grade materials

Mold modification allowed

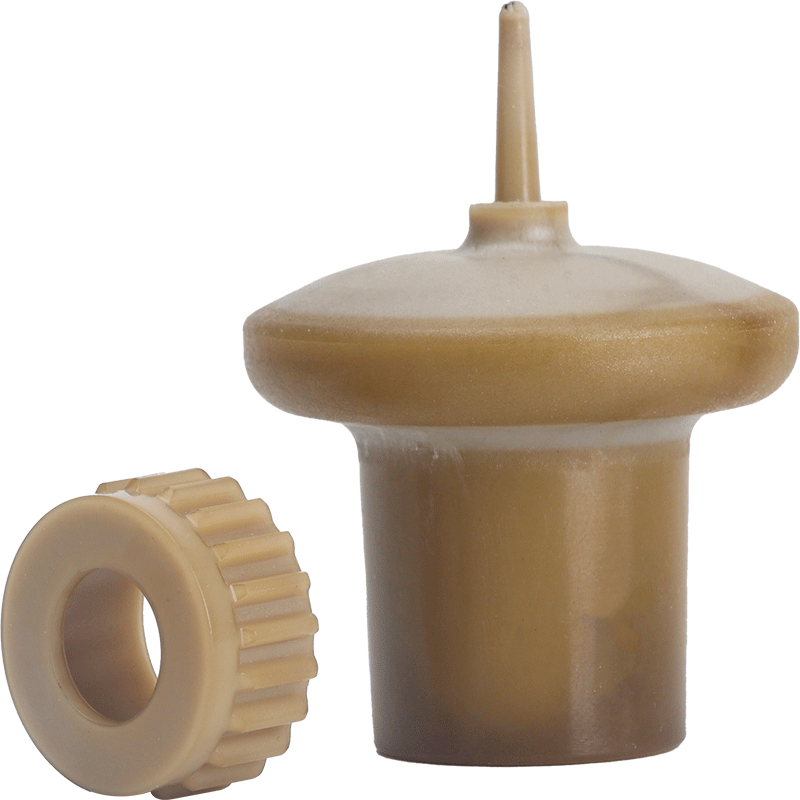

Mirco injection molding

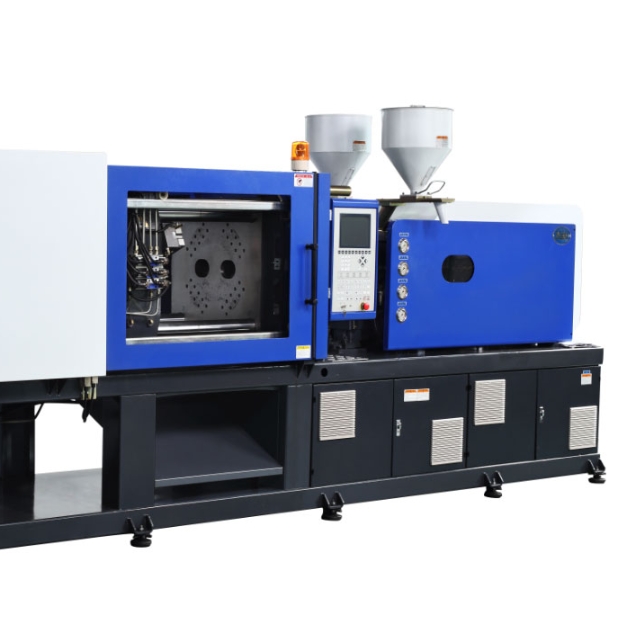

The injection molding process is the most common, most important and economical process for the mass production of plastics, especially high performance engineering plastics. We offer rapid tooling (prototype tooling), trial tooling ( bridge tooling ), hardened tooling, low volume production, high-volume production (mass production) and on-demand production.

What’s Injection Molding

Injection molding is a manufacturing process for producing parts by injecting material into a mold. Injection molding can be performed with a host of materials, including metals, elastomers, and most commonly thermoplastic and thermosetting polymers.

Learn More >>

Advantages of Injection Molding

Injection molding is hot popular for its high efficiency, complex part design, enhanced strength, flexibility material and color and lower cost.

Learn More >>

Materials Available for Injection Molding

HaoMolding has rich experience in injecting high-performance engineering materials. We stock common nylon with glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class, meeting all your needs for materials.

Learn More >>

Why Injection Molding Service at HaoMolding

Rapid Over-molding

Rapid over-molding for complex plastic parts.

Lead Time Short

Generally. it will take 2 weeks to 3 weeks

It can be shorter as per specific situation.

Cost Effective

When product quantity is over thousands

the unit price will be much lower than

other processes.

Free DFM Analysis

Expert feedback and free design for manufacturability(DFM) analysis.

Clamping Force Range

Min: 80 tons(10105mm-part)

Max: 480 tons(830*810mm-mold)

Micro Injection Molding

Micro injection molding greatly reduces the

production cost and shorten the mold developmenttime. It allows flexibility and quick-turnaround times.

Thermoplastic Materials

We have hundreds of different thermoplastic resins materials that are suitable for various part applications and industries. Customer-supplied materials are also accepted.

Learn More >>