Certainly! Here’s an overview of plastic molding and plastic mold manufacturers:

Plastic Molding:

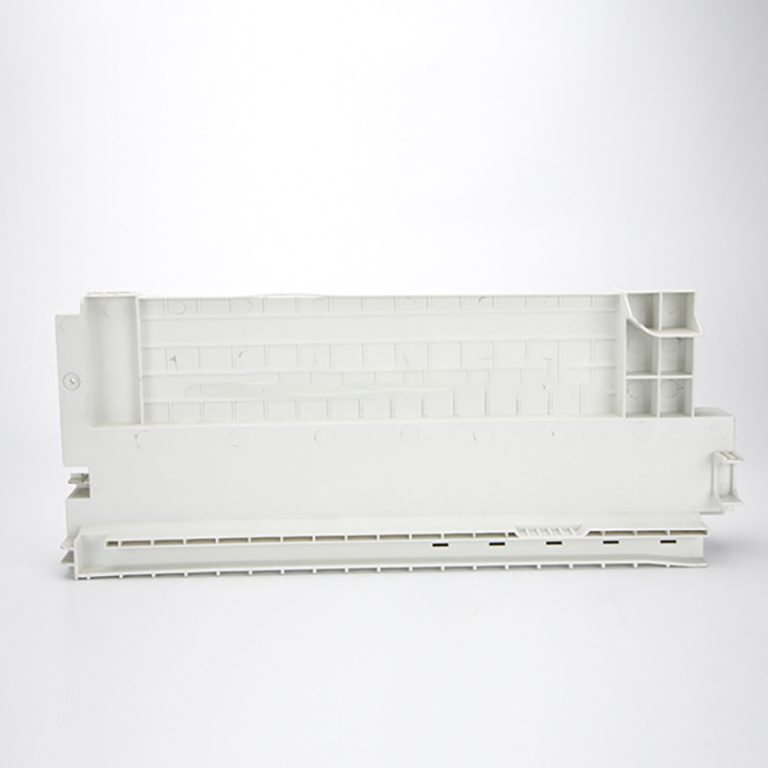

- Definition: Plastic molding, also known as injection molding, is a manufacturing process for producing parts by injecting molten material (typically plastic) into a mold cavity.

- Process Overview:

1.Injection: Molten plastic is injected into a mold under high pressure.

2.Cooling: The material solidifies inside the mold.

3.Ejection: The mold opens, and the part is ejected.

- Types of Plastic Molding:

4.Injection Molding: Most common, used for producing high volumes of parts with complex geometries.

5.Blow Molding: Used for producing hollow parts like bottles and containers.

6.Extrusion Molding: Continuous process for creating parts with consistent cross-sections.

7.Compression Molding: Suitable for larger parts and materials requiring higher temperatures.

- Applications: Widely used in automotive, consumer goods, electronics, medical devices, and more due to its versatility and ability to mass-produce complex parts.

Plastic Mold Manufacturer: - Role: A plastic mold manufacturer specializes in designing, manufacturing, and maintaining molds used in plastic molding processes.

- Expertise:

8.Design: Skilled in CAD/CAM software for mold design.

9.Manufacturing: Capable of precision machining and tooling.

10.Materials: Knowledgeable about various mold materials (e.g., steel, aluminum) and their properties.

11.Maintenance: Provides mold maintenance and repair services to ensure longevity and performance.

- Considerations when Choosing a Manufacturer:

12.Experience: Look for manufacturers with extensive experience in the industry and a proven track record.

13.Capabilities: Assess their capabilities in terms of mold size, complexity, and materials they can work with.

14.Quality Standards: Ensure they adhere to quality standards like ISO certifications.

15.Customer Support: Evaluate their ability to provide ongoing support, including maintenance and troubleshooting.

| Automotive Industry |

| Consumer Goods |

| Medical Industry |

| Aerospace |

| Industrial Equipment |

- Importance in Plastic Molding: The quality of the mold directly impacts the quality, consistency, and cost-effectiveness of the molded parts. Choosing the right manufacturer is crucial for achieving desired production outcomes.

In summary, plastic molding and plastic mold manufacturers play integral roles in various industries by enabling efficient production of plastic parts with diverse applications.