Table of Contents

Ishlab chiqarish uchun plastik inyeksion kalıplama qismlarining afzalliklari

Ikkinchidan, plastik inyeksion kalıplama tez va samarali jarayondir. Jarayon yuqori darajada avtomatlashtirilgan, ya’ni qismlarni tez va minimal inson aralashuvi bilan ishlab chiqarish mumkin. Bu uni yuqori hajmli ishlab chiqarish uchun ideal qiladi.

Mahsulot nomi

| rang | Plastik qarshi kalıplama qismlari |

| OEM/ODM | Plastik quyish qolipli qismlarni yaratish uchun dizayn masalalari |

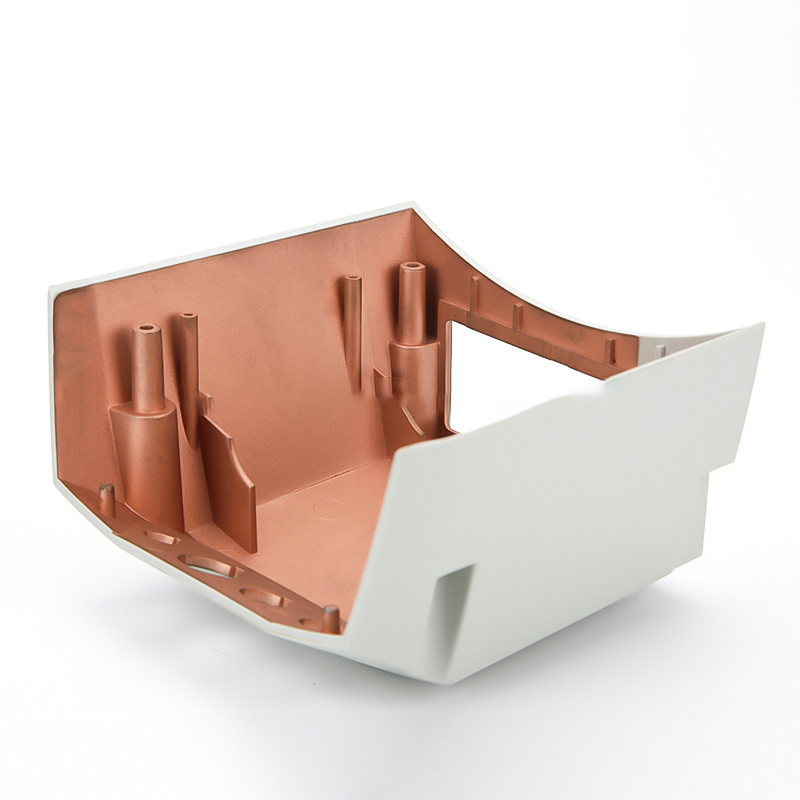

Plastik inyeksion kalıplama qismlarini yaratish murakkab jarayon bo’lib, turli dizayn elementlarini diqqat bilan ko’rib chiqishni talab qiladi. Materialni tanlashdan tortib qolib dizaynigacha, jarayonning har bir bosqichi eng yuqori sifatli mahsulotni ta’minlash uchun ehtiyotkorlik bilan rejalashtirilgan bo’lishi kerak. Plastmassa inyeksion kalıplama qismlarini yaratish uchun dizayndagi asosiy fikrlardan ba’zilari:

Material tanlash: Materialni tanlash plastik inyeksion kalıplama qismlarini yaratish uchun eng muhim dizayn masalalaridan biridir. Turli materiallar turli xil xususiyatlarga ega, shuning uchun dastur uchun to’g’ri materialni tanlash muhimdir. Materialni tanlashda mustahkamlik, moslashuvchanlik va xarajat kabi omillarni hisobga olish kerak.

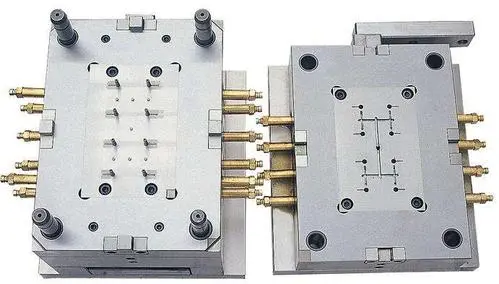

Qlip dizayni: Qolib dizayni plastik inyeksion kalıplanmış qismlarni yaratish uchun yana bir muhim e’tibor hisoblanadi. Kalıp, qismning kerakli shakli va o’lchamlari bilan ishlab chiqarilishini ta’minlash uchun mo’ljallangan bo’lishi kerak. Qolip, shuningdek, kerakli sirt qoplamasi bilan qismning ishlab chiqarilishini ta’minlash uchun mo’ljallangan bo’lishi kerak.

Jarayon parametrlari: Plastik qarshi kalıplanmış qismlarni yaratishda jarayon parametrlarini ham diqqat bilan ko’rib chiqish kerak. Ehtiyotkorlik bilan inyeksiya bosimi, quyish tezligi va sovutish vaqti detalning kerakli xususiyatlarga ega bo’lishini ta’minlash uchun ehtiyotkorlik bilan sozlanishi kerak.

Bular plastik inyeksion kalıplanmış qismlarni yaratish uchun dizayn mulohazalaridan bir nechtasi. Ushbu elementlarning har birini sinchkovlik bilan ko’rib chiqsangiz, sizning qismlaringiz eng yuqori sifat va ishlash bilan ishlab chiqarilishiga ishonch hosil qilishingiz mumkin.

The Design Considerations for Creating Plastic Injection Moulded Parts

Creating plastic injection moulded parts is a complex process that requires careful consideration of a variety of design elements. From the material selection to the mould design, each step of the process must be carefully planned to ensure the highest quality product. Here are some of the key design considerations for creating plastic injection moulded parts:

Material Selection: The material selection is one of the most important design considerations for creating plastic injection moulded parts. Different materials have different properties, so it’s important to select the right material for the application. Factors such as strength, flexibility, and cost should all be taken into account when selecting the material.

Mould Design: The mould design is another important consideration for creating plastic injection moulded parts. The mould must be designed to ensure that the part is produced with the desired shape and dimensions. The mould must also be designed to ensure that the part is produced with the desired surface finish.

Process Parameters: The process parameters must also be carefully considered when creating plastic injection moulded parts. The injection pressure, injection speed, and cooling time must all be carefully adjusted to ensure that the part is produced with the desired properties.

These are just a few of the design considerations for creating plastic injection moulded parts. By carefully considering each of these elements, you can ensure that your parts are produced with the highest quality and performance.