Plastik inyeksion kalıplamada ehtiyot qismlar sifatini nazorat qilishning ahamiyati

bizning xizmatlarimiz

| size | bir darcha xizmatlari |

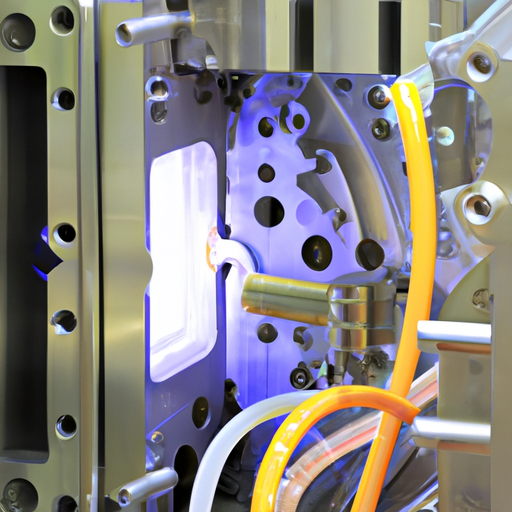

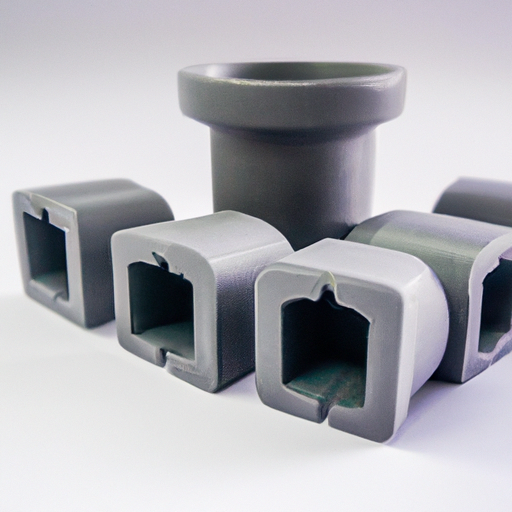

| moslashtirish | Sifatni nazorat qilish ehtiyot qismlarni plastik inyeksion kalıplamada muhim rol o’ynaydi. Yakuniy mahsulot talab qilinadigan texnik talablarga javob berishini ta’minlash uchun ishlab chiqarish jarayonida bir qator tekshiruvlar va sinovlarni o’z ichiga oladi. Sifatni nazorat qilish choralarini qo’llash orqali ishlab chiqaruvchilar har qanday nuqsonlarni yoki istalgan natijadan og’ishlarni aniqlashlari va bartaraf etishlari mumkin, bu faqat yuqori sifatli qismlar ishlab chiqarilishini ta’minlaydi. |

Plastik inyeksion kalıplamada sifat nazorati muhim bo’lishining asosiy sabablaridan biri nuqsonlarning oldini olishdir. Ehtiyot qismlardagi nuqsonlar ishlash bilan bog’liq muammolar, xavfsizlik xavfi va xarajatlarning oshishiga olib kelishi mumkin. Sifatni nazorat qilish choralarini qo’llash orqali ishlab chiqaruvchilar ishlab chiqarish jarayonining boshida yuzaga kelishi mumkin bo’lgan nuqsonlarni aniqlashlari va bartaraf etishlari mumkin, bu esa nuqsonli qismlarning bozorga etib borish xavfini minimallashtirishi mumkin. Bu nafaqat ishlab chiqaruvchining obro’sini saqlab qolishga yordam beradi, balki mijozlar ehtiyojini qondirishni ham ta’minlaydi.

Ehtiyot qismlarni plastik inyeksion kalıplamada sifat nazorati hal qiluvchi ahamiyatga ega bo’lgan yana bir sabab – mustahkamlikni saqlashdir. Ishlab chiqarish jarayonidagi izchillik har bir qismning talab qilinadigan texnik shartlarga javob berishini ta’minlash uchun muhim ahamiyatga ega. Harorat, bosim va sovutish vaqti kabi turli parametrlarni yaqindan kuzatib borish va nazorat qilish orqali ishlab chiqaruvchilar har bir qismning bir xil darajada aniqlik va sifat bilan ishlab chiqarilishini ta’minlashi mumkin. Bu izchillik, ayniqsa, boshqa komponentlarga mos kelishi yoki ishlashi kerak bo’lgan ehtiyot qismlarni ishlab chiqarishda muhim ahamiyatga ega.

Bundan tashqari, sifat nazorati ishlab chiqarish jarayonini optimallashtirishga yordam beradi. Ishlab chiqarish jarayonidagi ma’lumotlarni doimiy ravishda kuzatib borish va tahlil qilish orqali ishlab chiqaruvchilar takomillashtirish yo’nalishlarini aniqlashlari va tuzatish choralarini qo’llashlari mumkin. Bu samaradorlikni oshirishga, chiqindilarni kamaytirishga va ishlab chiqarish xarajatlarini kamaytirishga olib kelishi mumkin. Sifat nazorati, shuningdek, ishlab chiqaruvchilarga ishlab chiqarish jarayonida yuzaga kelishi mumkin bo’lgan har qanday muammo yoki to’siqlarni aniqlash imkonini beradi, bu ularga kechikishlar yoki uzilishlarning oldini olish uchun faol choralar ko’rish imkonini beradi.

Nuqsonlarning oldini olish, izchillikni saqlash va ishlab chiqarish jarayonini optimallashtirishdan tashqari, sifat nazorati ham sanoat standartlari va qoidalariga muvofiqligi. Ko’pgina sohalarda avtomobilsozlik, aerokosmik va tibbiyot sohalari kabi ehtiyot qismlar uchun maxsus talablar mavjud. Sifatni nazorat qilish chora-tadbirlarini amalga oshirish orqali ishlab chiqaruvchilar o’zlarining ehtiyot qismlari ushbu qat’iy talablarga javob berishini ta’minlashi mumkin, bu xavfsizlik, ishonchlilik va boshqa komponentlar bilan muvofiqligini ta’minlaydi.

Xulosa qilib aytganda, ehtiyot qismlarni plastik inyeksion kalıplamada sifat nazorati katta ahamiyatga ega. Bu nuqsonlarning oldini olishga, izchillikni saqlashga, ishlab chiqarish jarayonini optimallashtirishga va sanoat standartlariga muvofiqligini ta’minlashga yordam beradi. Kuchli sifat nazorati tizimini joriy qilish orqali ishlab chiqaruvchilar eng yuqori sifatdagi ehtiyot qismlarni ishlab chiqarishi, mijozlar talablarini qondirishi va bozorda o’z obro’sini saqlab qolishlari mumkin.

One of the primary reasons why quality control is essential in plastic injection molding is to prevent defects. Defects in spare parts can lead to performance issues, safety hazards, and increased costs. By implementing quality control measures, manufacturers can identify and address potential defects early in the production process, minimizing the risk of defective parts reaching the market. This not only helps to maintain the reputation of the manufacturer but also ensures customer satisfaction.

Another reason why quality control is crucial in spare parts plastic injection molding is to maintain consistency. Consistency in the production process is essential to ensure that each part meets the required specifications. By closely monitoring and controlling various parameters such as temperature, pressure, and cooling time, manufacturers can ensure that each part is produced with the same level of precision and quality. This consistency is particularly important when producing spare parts that need to fit or function with other components.

Furthermore, quality control helps to optimize the production process. By continuously monitoring and analyzing data from the manufacturing process, manufacturers can identify areas for improvement and implement corrective actions. This can lead to increased efficiency, reduced waste, and lower production costs. Quality control also allows manufacturers to identify any potential issues or bottlenecks in the production process, enabling them to take proactive measures to prevent delays or disruptions.

In addition to preventing defects, maintaining consistency, and optimizing the production process, quality control also ensures compliance with industry standards and regulations. Many industries have specific requirements for spare parts, such as automotive, aerospace, and medical sectors. By implementing quality control measures, manufacturers can ensure that their spare parts meet these stringent requirements, ensuring safety, reliability, and compatibility with other components.

In conclusion, quality control is of utmost importance in spare parts plastic injection molding. It helps to prevent defects, maintain consistency, optimize the production process, and ensure compliance with industry standards. By implementing a robust quality control system, manufacturers can produce spare parts of the highest quality, meeting customer expectations and maintaining their reputation in the market.