Vertikal plastmassa quyishning afzalliklari

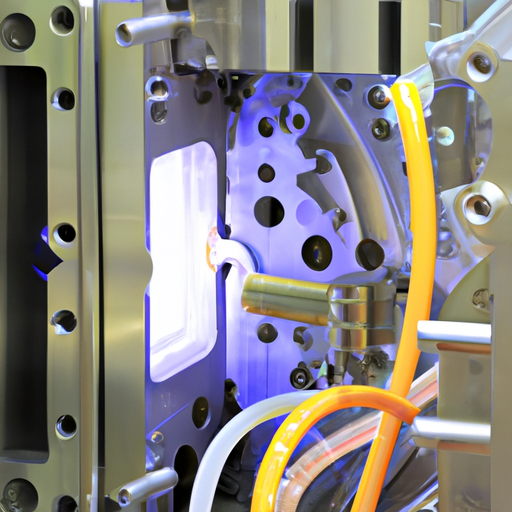

Vertikal plastik inyeksion kalıplama keng qo’llaniladigan ishlab chiqarish jarayoni bo’lib, boshqa usullarga nisbatan ko’plab afzalliklarga ega. Ushbu maqolada biz vertikal plastik inyeksion kalıplamaning asosiy afzalliklarini ko’rib chiqamiz.

bizning xizmatlarimiz

| size | bir darcha xizmatlari |

| moslashtirish | Bundan tashqari, vertikal plastik inyeksion kalıplama mog’orni yaxshiroq himoya qiladi va parvarish qilishni osonlashtiradi. Mog’orning vertikal yo’nalishi yaxshi sovutish va shamollatish imkonini beradi, bu esa haddan tashqari issiqlikning oldini olishga yordam beradi va mog’orning shikastlanish xavfini kamaytiradi. Bundan tashqari, vertikal dizayn qolipga kirish va tozalashni osonlashtiradi, ishlamay qolish va texnik xizmat ko’rsatish xarajatlarini kamaytiradi.

Vertikal plastik inyeksion kalıplama, shuningdek, bo’sh joy va oyoq izi nuqtai nazaridan afzalliklarni taqdim etadi. Mog’orning vertikal yo’nalishi gorizontal inyeksion kalıplama mashinalari bilan solishtirganda kamroq joyni talab qiladi, bu esa cheklangan maydonga ega bo’lgan ishlab chiqaruvchilar uchun kosmosdan tejamkorroq variantni yaratadi. Ushbu ixcham dizayn, shuningdek, mavjud ishlab chiqarish liniyalariga oson integratsiya qilish yoki maxsus vertikal qoliplash hujayralarini yaratish imkonini beradi. Xulosa qilib aytganda, vertikal plastik inyeksion kalıplama boshqa ishlab chiqarish usullariga nisbatan ko’plab afzalliklarni taqdim etadi. Uning murakkab va murakkab qismlarni yuqori aniqlik bilan ishlab chiqarish qobiliyati, material tanlashda ko’p qirrali va komponentlar integratsiyasi, samaradorlikni oshirish va ishlab chiqarish xarajatlarini kamaytirish, mog’orni yaxshiroq himoya qilish va oson parvarishlash va joyni tejaydigan dizayni ko’plab ishlab chiqaruvchilar uchun afzal qilingan tanlovdir. Viteslar, konnektorlar, tibbiy asboblar yoki boshqa murakkab qismlarni ishlab chiqarish uchun bo’ladimi, vertikal plastik qarshi kalıplama ishonchli va samarali echimni ta’minlaydi. |

Furthermore, vertical plastic injection molding offers better mold protection and easier maintenance. The vertical orientation of the mold allows for better cooling and venting, which helps prevent overheating and reduces the risk of mold damage. Additionally, the vertical design makes it easier to access and clean the mold, reducing downtime and maintenance costs.

Vertical plastic injection molding also offers advantages in terms of space and footprint. The vertical orientation of the mold requires less floor space compared to horizontal injection molding machines, making it a more space-efficient option for manufacturers with limited space. This compact design also allows for easier integration into existing production lines or the creation of dedicated vertical molding cells.

In conclusion, vertical plastic injection molding offers numerous advantages over other manufacturing methods. Its ability to produce complex and intricate parts with high precision, versatility in material selection and component integration, improved efficiency and reduced production costs, better mold protection and easier maintenance, and space-saving design make it a preferred choice for many manufacturers. Whether it is for producing gears, connectors, medical devices, or other intricate parts, vertical plastic injection molding provides a reliable and efficient solution.